Hesperian Health Guides

Details of How to Make Wheelchair Parts

HealthWiki > Disabled Village Children > Chapter 66: Designs for 6 Basic Wheelchairs > Details of How to Make Wheelchair Parts

Contents

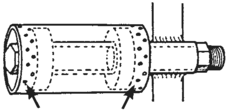

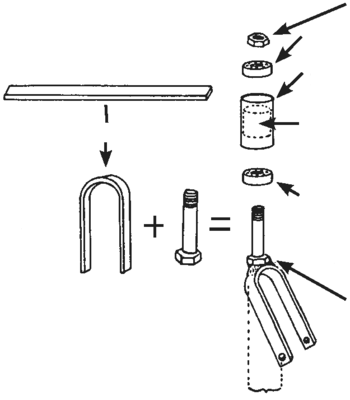

HEAVY-DUTY WHEEL HUBS

- A thick bolt should fit tightly inside bearing.

- Bearings should fit tightly inside outer steel tube.

- Carefully mark and drill the outer steel tube for spoke holes.

- Spacer tube fits over axle bolt and holds bearings against spoke heads.

holes for bicycle spokes

Note: Used sealed bearings with a ⅝" inner diameter can often be obtained free or at low cost from electrical tool and appliance repair shops. These used bearings often last longer than standard wheelchair bearings.

axle (steel bolt ⅝")

spacer tube

used sealed bearings

outer steel tube (1¼" thin-wall)

frame of chair

thick-wall tube welded to frame

locknut

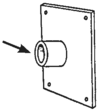

| To attach the heavy-duty hub to a wood chair, you can weld the thick-wall tube to a metal plate. The bigger the plate is the stronger the mount. |

|

The metal plate can be bolted onto the wood.

wood

axle |

|

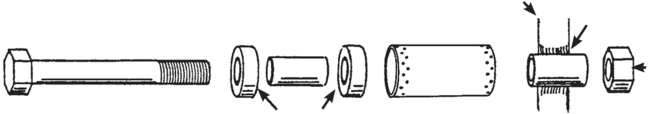

CASTER FORK AND HUBS

nut

sealed bearing

steel bar

galvanized steel tube for caster barrel

bend

⅝" bolt

A sleeve tube spot-welded to inside of barrel keeps bearings in place.

Drill at equal lengths.

Sealed bearings fit tightly inside caster hub and rest against inner sleeve tube.

Weld bolt to steel bar.

Caster axle fits tightly inside bearings.

Caster axle fits tightly inside bearings.

7 cm

Mount the caster axle at least 7 cm behind bolt. This helps prevent ‘flutter’ at higher speeds.

For slightly different designs, see:

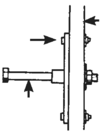

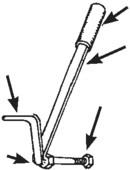

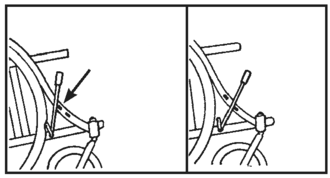

BRAKES

piece of rubber hose

bent piece of flat bar

flat or round steel bar

bolt for attaching to frame

weld |

Or steel rod can be bent like this for the brake. |

LOCKED

UNLOCKED

metal stops to hold brake in place

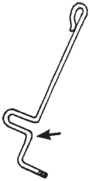

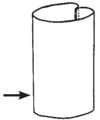

SEAT AND BACK MADE OF CANVAS (strong cloth)

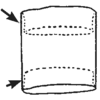

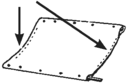

Cut canvas twice as wide as seat or back, allowing 4 cm extra on sides (for seams) and at least 20 cm longer on length. Sew canvas into a tube. |

Tuck in ends to add strength where wear is greatest. |

Sew seams here. |

Drill holes and screw rods to frame. |

CAUTION! Measure carefully. On a folding chair, the width of the seat and back control the width of the chair.

For designs of other wheelchair parts, see the following pages:

| wheels: |

footrests: |

| seats and backs: |

axle mounts: |

| tires: |

handrims: |

| armrests: |

cushions: |

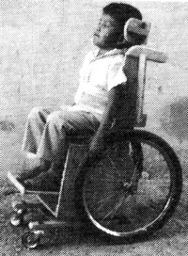

Examples of locally made wheelchairs

|

|

|

| The plywood wheelchair, with the armrest in place (left) and swung back (right). | A plywood wheelchair for a child with cerebral palsy with inner tube stretching aids to gently pull his feet and straighten his severe knee contractures. | |

|

|

|

| A bamboo hand-powered tricycle made at Viklang Kendra (People’s Village), Allahabad, India. | A wheelchair made completely of paper, including the wheels. Paper is glued together using rice flour in water (Zimbabwe). | A wood design of the square tube wheelchair, two Healthlink wheelchairs, and a trolley made from half of a plastic bucket and wood wheels. |

|

|

|

| A wood wheelchair in Thailand. The bicycle wheel axles are supported on both sides to keep them from bending. | A metal frame, wood wheel ‘trolley’ in Bangladesh. The rubber tube serves as a cushion and also as a toilet seat. | This trolley, also from Bangladesh, uses a cushion made of coconut fiber covered with rubber. |

For more examples of wheelchair designs, see:

- "The Changing Needs for Aids and Assistance"

- "Hip Contractures"

- "Moving About"

- "Self Care"

- "Keeping Active"

- "Prevention of Contractures"

- "Enrique's Story

- "Toilet Training"

- "Understanding Children with Disabilities"

- A Story to be Used with: "How Tomás and other children helped Julia go to school"

- "Making Sure Aids and Procedures Do More Good Than Harm"

This page was updated:25 Nov 2024