Hesperian Health Guides

Chapter 66: Designs for 6 Basic Wheelchairs

There are dozens of designs for low-cost, appropriate technology wheelchairs. Some are lower cost and more generally useful than others. In PROJIMO, we have built many different wheelchairs. In this chapter we give designs for 6 of the ones that we have found most useful. Each has advantages and disadvantages.

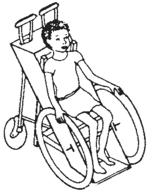

| HEALTHLINK wood wheelchair made from a child’s chair, bicycle wheels and axles at front, one rear caster |

|

| Advantages: The simplest and one of the cheapest chairs to make; easy to modify or adapt; very little welding needed; can be built in one day by someone with some carpentry skill; low cost. |

| Disadvantages: Single, small rear wheel makes it difficult for either the child or helper to push over rough ground or up curbs. Fixed footrest makes it hard for child to climb in and out without tipping chair forward when weight is on footrest. Sideboard makes transfers to side and lifting child from behind difficult. |

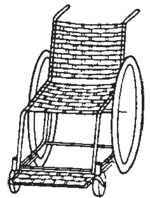

| Re-bar and woven plastic wheelchair steel construction rod frame with woven plastic seat, back, and footrest |

|

| Advantages: Simple design; fairly low-cost re-bar is easy to bend; plastic woven seat is comfortable and easy to clean; slide-away footrest makes getting in and out easier. |

| Disadvantages: Builder needs welding skills; relatively heavy and not as strong as tubing chairs. Big bumps may bend the chair out of shape. |

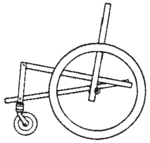

| Square metal tube wheelchair frame bolted together |

|

| Advantages: Strong, stable metal chair that can be built with nuts and bolts (welding needed only to attach front wheels). Flat surfaces make it easier to put on wood adaptations; fairly low cost. |

| Disadvantages: More work and skill needed than for above chairs; design more complex; slightly higher cost than wood chairs. |

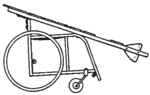

| Wheelchair with lying board made of steel tubing, with removable wood lying board |

|

| Advantages: Useful for active child who must lie face down to heal sores or stretch contractures. When board is removed, it is regular wheelchair; low cost; very adaptable. |

| Disadvantages: Requires welding (but a simpler model can be made of wood); does not fold; board takes up a lot of space; stiff ride. |

| Plywood frame wheelchair with 20 inch bicycle wheels and axles, and 2 front casters |

|

| Advantages: Attractive; lightweight; low cost, easy to make and adapt. Caster wheels in front (not in back) make it easier to go over rough ground and curbs. Adjustable push-away footrest makes positioning and getting in and out easy. |

| Disadvantages: Plywood and double casters increase cost (although it is still a cheap chair). Plywood (if not marine grade) may come apart in wet weather. Bicycle axles may bend or break with a heavy child or rough use. |

| Metal tube folding wheelchair made from thin wall steel tubing; strong axles with machinery bearings |

|

| Advantages: Chair folds for transporting or storage; very tough; flexible design good for uneven surfaces; good for side transfers; a very high-quality chair if well-made. |

| Disadvantages: Needs more skill (tube bending, welding, wheel spoking, etc.) to build; relatively costly; hard to adapt. |

This page was updated:19 Apr 2025