Hesperian Health Guides

Design Choices for Wheelchairs

HealthWiki > Disabled Village Children > Chapter 64: Decisions About Special Seats and Wheelchairs > Design Choices for Wheelchairs

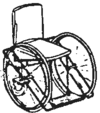

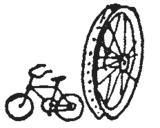

ContentsWHEEL SIZE AND POSITION | |

| 2 BIG WHEELS with 1 or 2 small caster wheels | DESIGN DETAILS |

INDOOR

OUTDOOR

one or 2 rear wheels

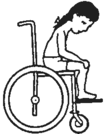

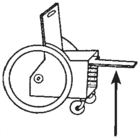

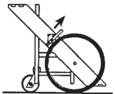

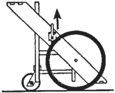

Rear wheel set back to avoid tipping backward on slopes

Child’s weight should be mostly over big wheels. |

|

| ADVANTAGES | DISADVANTAGES |

|

|

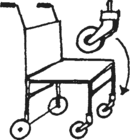

| 4 SMALL WHEELS | DESIGN DETAILS |

casters for easier turning |

Very simple temporary chairs can be made by putting 4 wheels on an ordinary wood chair. chair leg

pin

rod

wheels |

| ADVANTAGES | DISADVANTAGES |

|

|

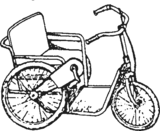

| 3 BIG WHEELS | DESIGN DETAILS |

hand crank and steering |

|

| ADVANTAGES | DISADVANTAGES |

|

|

BUILDING MATERIAL FOR FRAME | |

| STEEL TUBE | DESIGN DETAILS |

| |

| ADVANTAGES | DISADVANTAGES |

| A strong, long-lasting, fairly light chair can be made better and cheaper than most commercial chairs. |

|

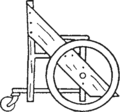

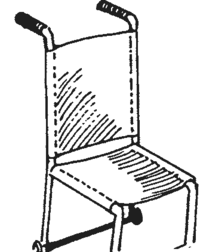

| WOOD | DESIGN DETAILS |

|

|

For wood design details, see "Health Link Wood Wheel Chair" and "Plywood Frame Wheel Chair" and references. wood chair model design |

| ADVANTAGES | DISADVANTAGES |

|

(For tighter joints and more adaptability, use nuts and bolts instead of nails.) |

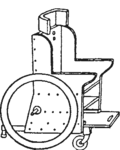

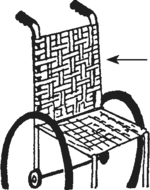

| RE-BAR (metal reinforcing rod used to strengthen cement) | DESIGN DETAILS |

woven plastic seat and back

footrest slides in and out |

Design can be the same as for metal tube chairs, but it is easier to adapt because the re-bar is easy to bend. |

| ADVANTAGES | DISADVANTAGES |

|

|

| PVC PIPE (plastic water pipe) | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

SEATS AND BACKS |

|

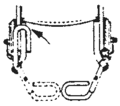

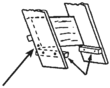

| SOFT CANVAS OR LEATHER STRETCHED BETWEEN SUPPORTS | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

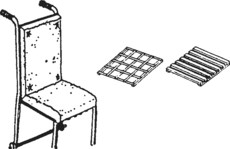

| FIRM (BUT PADDED) BACK AND SEAT | DESIGN DETAILS |

other possibilities for use under cushion

metal slats

wood slats |

|

| ADVANTAGES | DISADVANTAGES |

|

|

| WOVEN SEAT AND BACK | DESIGN DETAILS |

strips of old inner tube stretched tight |

|

| ADVANTAGES | DISADVANTAGES |

|

|

TIRES | |

| PUMP-UP WITH AIR BALLOON TIRES | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

| SOLID TIRES (standard wheelchair wheels) | DESIGN DETAILS |

|

Buy from wheelchair supply center to fit diameter and width of rim. |

| ADVANTAGES | DISADVANTAGES |

|

|

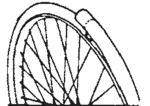

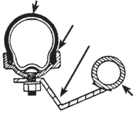

| RUBBER HOSE INSIDE BICYCLE TIRE | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

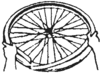

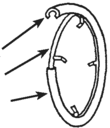

| THIN STRIP OF OLD CAR TIRE | DESIGN DETAILS |

|

Wire ends together. |

| ADVANTAGES | DISADVANTAGES |

Sink bolt head,

and/or bolt the ends. |

|

| LARGE MACHINERY FANBELT discarded |

DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

| PIECE OF OLD BICYCLE OR SCOOTER TIRE | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

BIG WHEELS | |

| STANDARD FACTORY-MADE WHEELCHAIR WHEELS | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

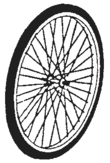

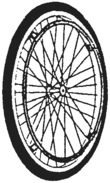

| BICYCLE WHEELS (rims and spokes) | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

| BICYCLE RIMS WITH WOODEN SPOKES | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

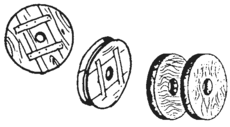

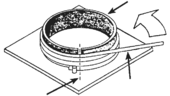

| WOOD WHEELS — big or small | DESIGN DETAILS |

|

tire

edge of wheel |

| ADVANTAGES | DISADVANTAGES |

|

|

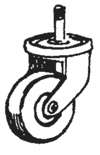

CASTERS AND WHEELS | |

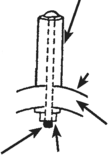

| STANDARD WHEELCHAIR CASTER WHEELS | DESIGN DETAILS |

(“Caster” means that the wheel can swing in different directions for making turns.) |

|

| ADVANTAGES | DISADVANTAGES |

|

|

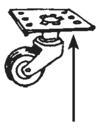

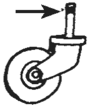

| CASTERS FROM OTHER (non-wheelchair) EQUIPMENT (used or new) | DESIGN DETAILS |

for mounting on wood frame

caster welded to metal plate for screwing to wood  for mounting into metal tube frame |

|

| ADVANTAGES | DISADVANTAGES |

|

|

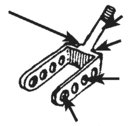

| BENT AND WELDED STEEL CASTER FORKS | DESIGN DETAILS |

30° angle

bolt

strong bronze weld

bolt

holes to make fork weigh less

hole sized to fit axle |

|

| ADVANTAGES | DISADVANTAGES |

|

|

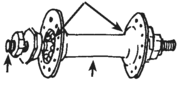

HUBS, BEARINGS, AND AXLES | |

| STANDARD WHEELCHAIR BEARINGS | DESIGN DETAILS |

ball bearings

ball bearings at each end of hub

axle

hub |

axle does not move

turning wheel |

| ADVANTAGES | DISADVANTAGES |

|

|

| BICYCLE BEARINGS AND AXLES | DESIGN DETAILS |

front wheel axle

hub

axle |

For mounting alternatives, see wheelchair designs "Design Choices for Wheelchairs" and "Health Link Wood Wheel Chair". |

| ADVANTAGES | DISADVANTAGES |

|

|

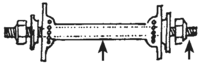

| REAR BICYCLE WHEEL AXLE AND BEARINGS | DESIGN DETAILS |

hub

metal plate

wheelchair frame |

|

| ADVANTAGES | DISADVANTAGES |

|

|

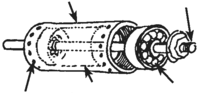

| USED MACHINERY BEARINGS | DESIGN DETAILS |

thin metal pipe

⅝ inch bolt

holes for spokes

narrower tube to hold bearings apart

bearing |

|

| ADVANTAGES | DISADVANTAGES |

|

|

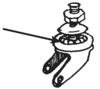

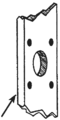

| WOOD BEARING | DESIGN DETAILS |

washer

bolt (welded to fork)

oil-soaked wood tube

metal fork

wood wheel

(oil-soaked hole) bolt spot welded to fork |

|

| ADVANTAGES | DISADVANTAGES |

|

|

SUPPORT OF AXLES | |

| AXLE SUPPORTED ON ONE SIDE ONLY | DESIGN DETAILS |

nut

axle passes through metal tube welded to frame

This is the standard mount for factory-built chairs. |

|

| ADVANTAGES | DISADVANTAGES |

Pass pipe through a wood frame,

or weld to metal frame. |

|

| AXLE SUPPORTED ON BOTH SIDES | DESIGN DETAILS |

This can be done in several ways:

metal strips on wood frame

metal tube on tube frame |

single caster

wood on wood frame |

| ADVANTAGES | DISADVANTAGES |

re-bar loop on re-bar frame |

|

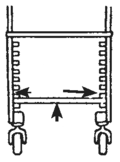

TO FOLD OR NOT TO FOLD | |

| A TYPICAL FOLDING CHAIR | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

Folding:

Non-folding:

|

Folding:

Non-folding:

|

ARMRESTS | |

| NO ARMRESTS | DESIGN DETAILS |

|

Note: Many chairs are built so that armrests are part of the main structure and strength of the chair. The armrests cannot be easily removed, even though this might benefit the child. Carefully consider the child’s need for armrests before buying or making a chair. |

| ADVANTAGES | DISADVANTAGES |

|

|

| FIXED ARMRESTS | DESIGN DETAILS |

Fixed armrests |

The so-called “desk arm” lets front of chair fit under a table—but is often too high or too short. |

| ADVANTAGES | DISADVANTAGES |

They can sometimes be used for attaching a removable table. |

|

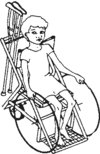

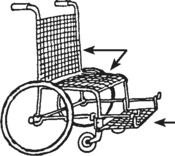

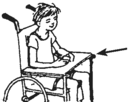

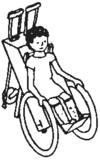

| REMOVABLE ARMRESTS | DESIGN DETAILS |

adjustable armrest

Armrest fits into these tubes. |

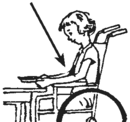

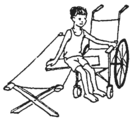

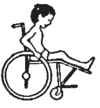

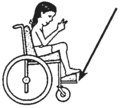

child transferring from a chair on a board — one armrest removed |

| ADVANTAGES | DISADVANTAGES |

|

|

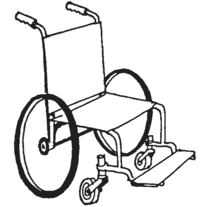

FOOTRESTS | |

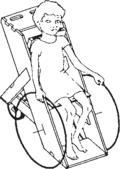

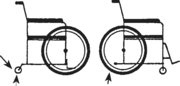

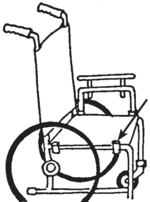

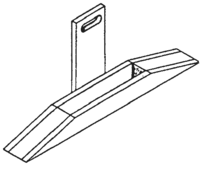

| POSITIONS | DESIGN DETAILS |

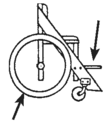

In adult chairs, footrests often angle legs forward to leave room for casters.

For a small child, often footrests can position legs straight down. This is important in many cases.

A larger child may need to sit on cushions so that his feet are above the casters. |

|

| ADVANTAGES | DISADVANTAGES |

A footrest like this,

may help feet like these. |

|

| FIXED POSITION FOOTRESTS | DESIGN DETAILS |

|

The height of the rests should be carefully measured to fit the child who will use them. (For measurements, see "Fitting the Chair to the Child: Measurements".)  |

|

| ADVANTAGES | DISADVANTAGES |

|

|

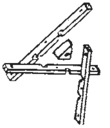

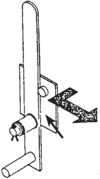

| REMOVABLE OR SWING-AWAY FOOTRESTS | DESIGN DETAILS |

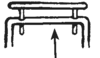

back-stop for feet

wood chair swing-away footrest

pin on which footrest swings

stops |

There are many designs. Here we show one for the wood chair shown above and one designed for a metal chair. Other designs for sliding or swing-away footrests are on pages "Re-bar and Woven Plastic Wheel Chairs", and "Whirlwind Steel Tube Wheel Chair". |

| ADVANTAGES | DISADVANTAGES |

|

|

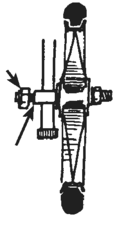

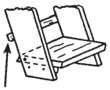

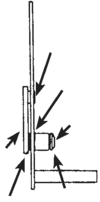

| ADJUSTABLE FOOTRESTS | DESIGN DETAILS |

hand hole for pulling

Footrest pulls out and slips back out of way.

FRONT VIEW

strips of wood to form slots

adjustable height |

There are many designs. Here is one of the simplest, for a plywood chair.  For straight leg sitting, a longer board fits into high slots. |

| ADVANTAGES | DISADVANTAGES |

leg board for both legs

for one leg |

|

| NO FOOTRESTS | DESIGN DETAILS |

|

|

| ADVANTAGES | DISADVANTAGES |

|

|

PARKING BRAKES | |

| LEVER BRAKES | DESIGN DETAILS |

|

Brake for wooden chair  off

on  |

There are many brake designs. This one is from Healthlink Worldwide. Two others are on "Details of How to Make Wheel Chair Parts".  push handle out and up

metal plate

SIDE VIEW

catch

weld

pivot

split pin

washer

metal plate |

| ADVANTAGES | DISADVANTAGES |

|

|

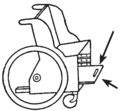

| PARKING BLOCK | DESIGN DETAILS |

|

Brakes on wheelchairs are for keeping the chair from rolling when getting in or out, or stopped on a hill. The simplest form of brake is a parking block that keeps the wheel from turning.  |

| ADVANTAGES | DISADVANTAGES |

|

|

HANDRIMS FOR PUSHING | |

| HANDRIMS | DESIGN DETAILS |

|

Designs taken from Healthlink Worldwide.  jig for bending tube

Cut down this line before removing from jig. Weld ends.

Wrap tube around several times to make several rims at once. |

| ADVANTAGES | DISADVANTAGES |

tire

Attach rim with metal brackets like this.

bracket

rim |

|

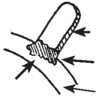

| HANDRIM GRIP IMPROVERS | DESIGN DETAILS |

rim pegs

wood or rubber tube

rim

Posts can be bolted or welded onto rim.

nut

bolt |

Cut a piece of rubber hose lengthwise and tape it onto rim.  cut

rim

hose

metal post

welded

onto rim

Posts can be bolted or welded onto rim. |

| ADVANTAGES | DISADVANTAGES |

|

strip of inner tube

rim

wrap

|