Hesperian Health Guides

Making the upper parts of shoes

HealthWiki > Workers' Guide to Health and Safety > Chapter 6: Shoe factories > Making the upper parts of shoes

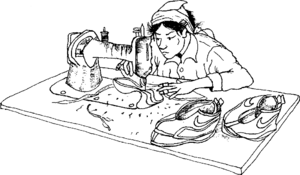

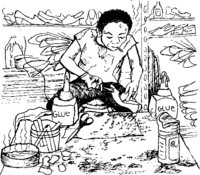

Workers cut, sort, and prepare the material of the upper and lining. The leather, cloth, and synthetic materials are cut to pattern on presses with sharp molds. Then the leather is thinned at the seams to make it easier to sew or glue. The lining is hot-pressed onto the pieces of material to be sewn. Then the different pieces of the upper are sewn or glued together.

Many different sewing machines are used to sew the upper parts of shoes. They are very powerful machines. All sewing machines should have guards around the needle and on the machine to protect workers from injuries.

Machine injuries

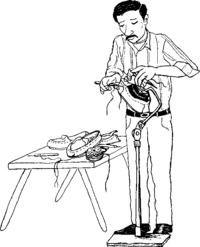

Eyelets, rivets, and ventilation openings in shoes are made on a loud, puncturing machine. The sewn uppers are then put on a mold, and the insole is nailed onto the mold.

The upper will then go through several shaping machines which heat the material and make it smooth. Stiffeners might be added to the heel and toe so they hold their shapes better. For leather shoes, hot cork is spread on the bottom of the insole.

Presses, stampers, rollers, riveters, sewing machines, die cutters, and other cutting tools can cause serious injury to workers’ hands. Sewing machines used to make shoes are powerful and use large needles that can cause severe harm to machine operators. The belts can catch workers’ hair or clothing and cause serious injury.

The hole-making machine and the nail machine are not sharp. But to make the holes in the upper and the insole, these machines use a lot of pressure. They also vibrate when they come down fast and hard on the material. Fingers can easily be caught in these machines, crushing them. Over time, the vibration damages nerves and can reduce the amount of blood that goes to the fingers, causing vibration-induced white finger (VWF) where the fingers tingle, hurt, or lose feeling. In the worst case, you can no longer hold objects or use your hands.

Injuries from cutting, crushing, and catching can be prevented. Machines need:

- guards on the needle areas and on the v-belts above and below the table.

- 2-handed controls on cutting, puncturing, nailing, and stamping machines.

- electric or other sensors to shut off power to a machine if the worker’s body is in the wrong place.

To prevent injuries to workers who are cleaning, fixing, or adjusting machines, it is important to follow lock out and tag out procedures for repair and maintenance work.

Strain and overuse injuries

Workers often sit or stand in the same position all day. If you can sit, chairs might not support your back and legs. In badly equipped factories, you might have only short stools instead of chairs, causing neck, back, leg, and knee pain.

See Chapter 7: Ergonomics to find ways to prevent injuries, such as:

- Rotate jobs during the day so no one does any job too long.

- Demand that the factory provide you with chairs and equipment that fit your body and your job.

- Set up your work area so you have what you need close at hand, and you do not have to reach, bend, or twist too much.

- Exercise to stretch and strengthen your muscles.

Some workers sew and glue shoes at home or in other people’s homes. Homework may give workers some flexibility with their time, but it also increases problems from strain and overuse injuries and exposure to chemicals. See Chapter 20: Doing factory work at home for ideas on setting up a comfortable and safe area in your house where you can work while reducing the health dangers of homework.

Dangers from dust

Cutting, buffing, and skiving (thinning seam edges) generate a lot of dust and small bits of material. Breathing these can cause irritation and other breathing problems. Breathing leather dust, which may contain heavy metals such as chromium, nickel, cadmium, and other chemicals used to tan leather, can cause problems for very young, pregnant, or older workers, and over time can cause skin irritation and allergies, sinus and nasal cancers, and other problems.

- An extractor can remove most of the dust from the workstation and area around it.

- A cloth over your nose and mouth may keep a little of the dust out, but it does not protect you very well. Use a dust mask that fits tightly over your nose and mouth.

- Use a vacuum cleaner or at least a damp cloth to clean the dust from surfaces around your work area at least 2 times during your shift.

- Use leather that was tanned without heavy metals and toxic chemicals.

- Wash chemicals and dust off your hands regularly, especially before eating or drinking.

Dangers from noise

Shoe factory workers operate many large and noisy machines. When possible, noise should be controlled at the source by enclosing and insulating the machine. Well-maintained machines make less noise. (See Chapter 13: Noise.)

- Ask the boss to measure noise at different places around the factory.

- Where it is too loud, workers should wear earplugs or earmuffs.