Hesperian Health Guides

Chapter 7: Ergonomics

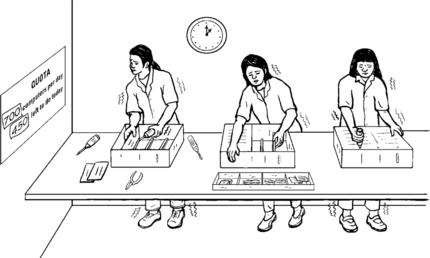

We are not machines. When workers do the same work over and over without enough rest, our bodies become tired and hurt. Our mental health can suffer, too (see Chapter 27: Stress and mental health).

Ergonomics helps us understand how work can hurt our bodies and what we can do to reduce and prevent injuries from repetitive work and overuse of our muscles, joints, and tendons.

Tired eyes and muscles that have a sensation of discomfort are the first signs that work is pushing you past your body’s limits. Eye and body strain, aches, tingling sensations, numbness, weakness, or pain in any part of your body are signs that your work is injuring you.

Ergonomic injuries can be prevented by making changes to the way work is done, improving our postures and how we move our bodies, and by ensuring tools, equipment, and workstations fit workers and the jobs they do. Anything that reduces the stress and strain on your body can help protect you.

If you already have pain, see a health worker and also read Stretches and massage reduce pain for movements and treatment that can help you feel better.

Small changes make a big difference

Working as a sewing machine operator in a garment factory in Oakland, USA was hard work. We would get there early and leave late, and every day our bodies hurt. But it was a good, steady paycheck.

We heard about an organization called the Asian Immigrant Women Advocates (AIWA) which was helping people in other factories in Oakland. When we first met them, they listened to us talk about our work and our jobs. For so long we felt that nobody cared about our problems, but AIWA did. We could not stop ourselves from crying during that meeting.

Then we met women from other factories. We talked about our aching shoulders, backs and arms, and the constant pain in our elbows, wrists, and hands. We talked about going home and being too tired to care for ourselves and our families. We learned we were not alone in our pain.

AIWA connected us with the Ergonomics Program at the University of California. They taught us about our bodies and how the workplace could be changed so we didn’t have to live with pain.

We discussed changes needed at our factory. We focused on reducing knee pain because everybody had it, and decided to try padding the knee switches on our machines. It worked! The very next day we had a little less pain. Such a small change made a real difference.

Slowly we began to push for other changes. We put footrests under the machines and got new, tilted tables so we could see our work better without bending forward. We even got padded and adjustable chairs!

Before AIWA, we never knew the power we had to improve our workplace. We thought pain from working was just the way work was. This lesson we learned from the project was something we took with us even after we left the factory and it has changed our lives.