Hesperian Health Guides

Assembling the printed circuit boards

HealthWiki > Workers' Guide to Health and Safety > Chapter 4: Electronics factories > Assembling the printed circuit boards

Contents

Soldering

Soldering means melting a little bit of metal to make a bridge connecting 2 different components. Solder is usually tin, a mixture of tin and lead, or a lead-free mix of copper and other metals. Soldering can be done manually or by machines.

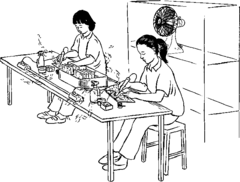

| Hand soldering Workers who solder by hand need mounted extractors on the soldering iron, strong local extractors, and respirators. If you notice signs that you are breathing in chemicals, stop working and improve your ventilation or PPE. |

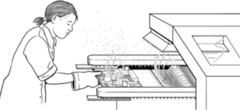

Machine soldering Wave soldering machines and other machines that solder should have strong local ventilation. PrCBs should rest in a well-ventilated area after they are soldered until they stop off-gassing. |

|

|

Soldering can hurt workers’ health

Flux and solder contain chemicals which can irritate your skin or lungs, immediately or later. They also contain chemicals that can cause chronic health problems. Rosin in flux and lead in solder are 2 of the chemicals that we know cause health problems in the soldering area.

Heating flux and solder releases fumes. Signs you are breathing the chemicals in flux and solder are:

- headaches

- nose bleeds

- problems breathing

- feeling tired and weak

- sore throat

- red and irritated eyes

- skin rashes

If you have any of these or other problems, tell your health and safety committee and boss. Talk to a health worker about where you work, what you do, and the chemicals you are exposed to. Smoking or just being around smoke will worsen these problems.

If your boss makes no changes to the workplace and you keep breathing the chemicals in flux and solder, you are likely to develop other health problems.

|

Record all health problems and changes in solders and fluxes in your health notebook. |

Protect workers from the dangers of soldering

Soldering is safer when flux does not contain rosin and solder does not contain lead. We know these materials are too dangerous to use.

Soldering can be made safer when workstations have good local and general ventilation (see Chapter 17: Ventilation) and workers have the correct, well-fitting personal protective equipment for the chemicals they use (see Chapter 18). When workers can tell the boss and the health and safety committee about safety issues, and get them resolved, everybody is safer.

Soldering can also be made safer by:

- turning the heat down on the soldering iron, so less fume is released into the air.

- "following the air" (see the activity Follow the air!) to check your local ventilation, and organizing to improve ventilation for everyone.

- finding out the dangers of the chemicals in your flux and solder. Look them up in the chemical charts, get an SDS, try other resources, and organize to get safer flux and solder.

Testing the PrCBs

Workers check the boards and their components visually and electronically before they are assembled or packaged for shipping. Lifting, checking, and removing the PrCBs can lead to muscle strain and overuse injuries. Often, to prevent static electricity from damaging the boards, workers are required to wear grounding wrist cords. The wrist cords contain nickel, a chemical that can irritate the skin.

- Adjust carts, work tables, and chairs to limit the amount of lifting and twisting you must do. (See Chapter 7: Ergonomics.)

- Wear gloves to protect your hands from the hard edges of the fiberglass boards.

- If you already have or develop an allergy to nickel, ask for a nickel-free grounding cord.