Hesperian Health Guides

Chapter 4: Electronics factories

Millions of people work in electronics factories, making the phones and devices we use every day. Our world economies depend on them. So why should workers continue to be made sick by chemicals used in making electronics, repetitive stress injuries, low pay, and bad living and working conditions? Ensuring their health and well-being should be a priority for governments, corporations, and managers of electronics factories.

To improve the health of workers in electronics factories:

- Governments and the ILO must regularly assess dangers in electronics factories and push factories and brands to improve working conditions. Governments must provide medical and social support for workers made sick by their work and ensure compensation for them and their families.

- Brands must make sure factories follow local and international labor, occupational safety and health, and environmental standards. They should design products to be made without toxic materials, to last a long time, and to be safely recycled.

- Factories must comply with labor, occupational safety and health, and environmental laws. They should disclose all the chemicals they use, and where and how they are used (including byproducts and disposal) to workers, communities, and the government. They should share monitoring information about exposure and illness with workers, communities, and the government.

- Workers must actively monitor their health and factory conditions. They should organize safety committees and unions in electronics factories.

Electronics factories may look safe but they are not

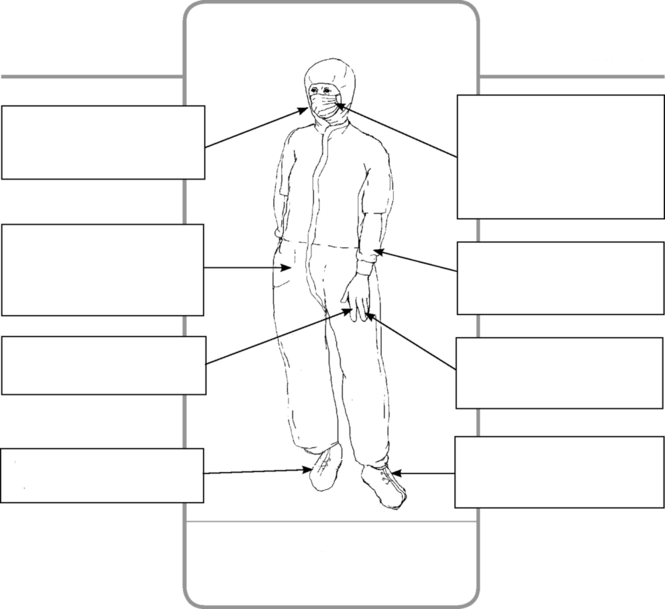

It is difficult for workers to know how they come in contact with chemicals in electronics factories because the factories look so safe. The rooms where many of the processes take place are very clean, with controlled temperature and humidity. Workers are covered from head to toe with special clothing which they are told protects them from dangers at work. Many processes are done by machines.

Electronics factories are set up to protect the delicate materials inside electronics, not necessarily the workers. For information about personal protective equipment (PPE), see Chapter 18.