Hesperian Health Guides

Other Ways of Making Artificial Limbs

HealthWiki > Disabled Village Children > Chapter 67: Artificial Legs > Other Ways of Making Artificial Limbs

Contents

Wooden legs

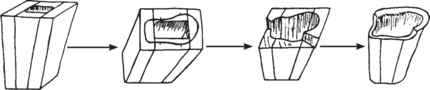

The oldest, traditional way of making artificial limbs is to make the socket out of wood.

This is best learned from a skilled craftsperson. Unfortunately, this is a skill that is difficult to learn from a book. A book that describes the method step-by-step is Manual of Above-Knee Wood Socket Prosthetics by Miles Anderson, John Bray, and Charles Hennesey. It has gone out of print, but you may still be able to find it. Unfortunately, the methods described are complex and require a lot of special equipment. However, perhaps they could be simplified. (We have not tried this method.)

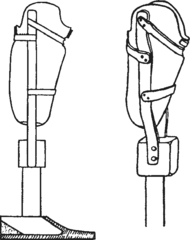

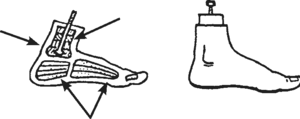

Leather socket: Self-adjusting prosthesis

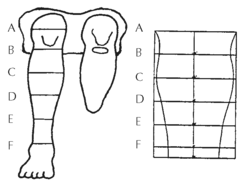

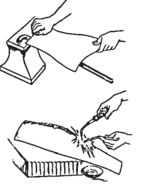

This method uses flat metal bars, a wood post, and a thick, firm leather socket. To form the socket, wet leather is stretched over a plaster mold of the stump. Methods are clearly and simply described in Simple Below-knee Prosthesis Manufacture. (Manual out of print)

A leather socket has several advantages. Leather is available almost everywhere, is more comfortable in hot weather, and can easily be adjusted to the stump as it becomes smaller. Also, leather is soft and easily takes the shape of the stump, and therefore self-corrects molding mistakes.

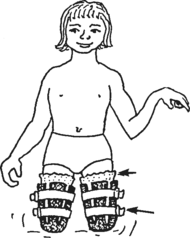

Stump protectors from old tires

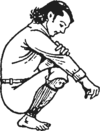

For a child with both legs amputated above the knee, short artificial limbs or even simple “stump protectors” may allow her to move about easier than long leg limbs.

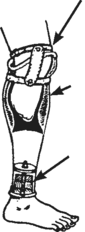

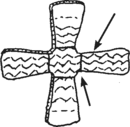

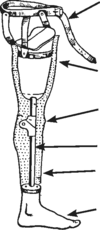

Jaipur limb

The Jaipur limb was developed in Jaipur, India to meet the need for a limb that would (1) allow working barefoot in rice paddies, (2) look like a real bare foot, (3) bend at the foot in all directions enough so the person can squat easily and walk firmly on uneven ground, and (4) be low cost and quick to make.

| THE JAIPUR FOOT | |

vulcanized rubber coating

wood

rubber core |

squatting |

| The foot is made of wood and sponge rubber and then vulcanized (heat molded) with rubber, using a metal mold. The rubber gives the foot its life-like form and color and makes it strong and waterproof. | |

To make the Jaipur limb requires a lot of skill as well as special equipment. But once a shop is set up and persons trained, the limb can be made at very low cost, and fitted very quickly (one hour from the first measurements until the person walks away on his new limb). For instructions, contact Rehab Centre, SMS Medical College, Jaipur 302004, India.

Ideas for a limb-making shop. In "Examples of Community-Directed Programs" there is a description of the OHI prosthetics shop in Thailand, where workers with amputations make the bamboo and above-knee adjustable limbs shown in this chapter.