Hesperian Health Guides

Above-Knee Artificial Limbs

| 1. A bamboo or PVC plastic tube above-knee limb can be made in much the same way as for the below-knee limb. | ||

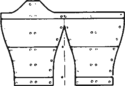

| BACK VIEW |

FRONT VIEW | |

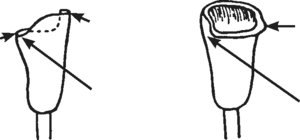

| The top edge of the socket should be rounded to form a wide lip on the back, where the butt can sit. Weight bearing should be on the butt bone and over the entire stump—and not just on the end of the stump. |  | |

| NOTE: In some countries, thin plastic cuffs the right shape for socket tops can be purchased in different sizes from orthopedic suppliers. They can be placed around the leg before casting and can be re-used. Ask for “prefabricated ishial weightbearing cuffs.” |  | |

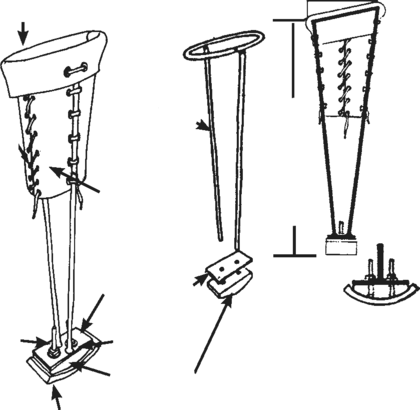

| 2. A leather and metal rod limb (adapted from Simple Prosthesis Manufacture). |

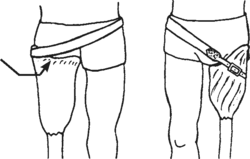

| MEASUREMENTS |

stand with hips level

distance

around hip

leg length

and

across hip |

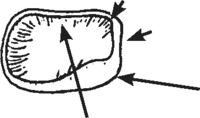

Note: The socket is open at the bottom of the stump. This makes it cooler than the one above, and also allows for growth. |

| To make sleeve, draw on paper a design like this based on A, B, and C stump measurements. Then copy onto leather and cut it out. |

A

B

C

|

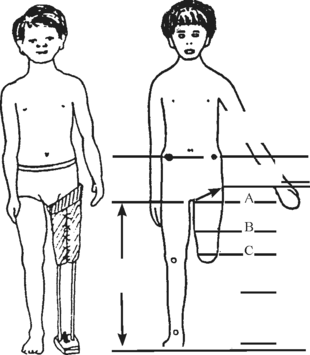

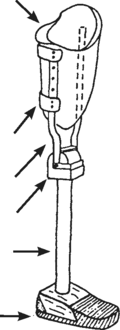

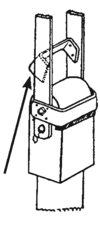

Above-knee limb with knee joint (for older children and adults)

| SIDE VIEW | FRONT VIEW |

Socket piece of leather (see below). (It can also be made of plaster, resin, or wood.)

support strips of metal

flat metal bars

knee joint

wood

wood and rubber foot |

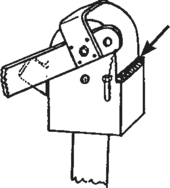

To help keep knee from bending when weight is on it, stretch a piece of rubber across front of knee.

strip of car tire inner tube

leather

(for very short stumps only) |

| Adapted from the OHI Manual: Simple Above-knee Prosthesis Manufacture. (Manual out of print) |

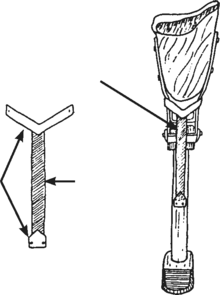

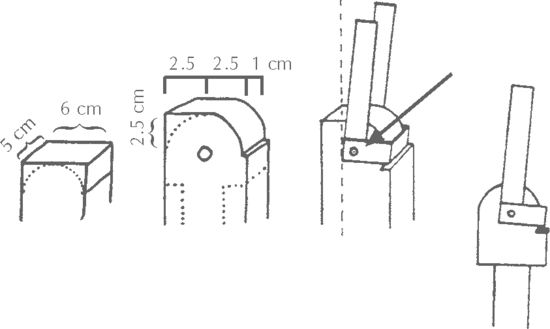

Making the knee joint:

Note: This is a simple design for a knee joint. Knee joints that work well are hard to make and you may need to experiment a lot. Perhaps you can re-use a joint from an old limb that is not being used.

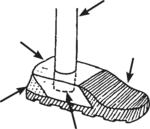

FEET

Putting feet on artificial legs makes them look better (with shoes, sandals, or boots). Also, the wide base helps prevent the leg from sinking into mud or sand. A well-made, flexible foot can make walking easier. Here are 2 possibilities.

lightweight spongy rubber

wood block (Use strong wood that will not crack.)

leg pole

old car tire (one piece)

Note: By putting the pole through the foot, if the foot breaks off the person can keep walking. |

The sponge rubber over the heel and toe lets the foot bend for smoother walking.

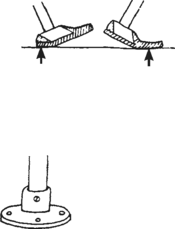

To mount a foot on a plastic PVC tube, use a flat metal pipe base like this.

|

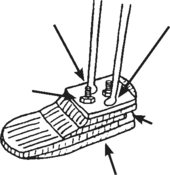

| A foot can also be made for a metal-rod leg. Here is one possibility. |

metal plate

weld

Leave open space above bottom sole for flexible heel.

3 or 4 layers of car tire, cut to allow flexibility of toes and heel.

Bolts should pass through all but the last layer of rubber. |