Hesperian Health Guides

Keeping Cost Down and Quality Up

HealthWiki > Disabled Village Children > Chapter 64: Decisions About Special Seats and Wheelchairs > Keeping Cost Down and Quality Up

Factory-made or homemade wheelchairs?

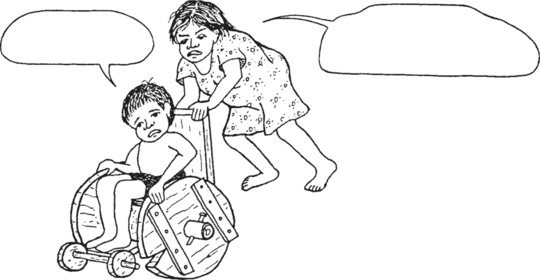

Often you can save money by making your own wheelchair or by asking a local craftsperson to make one. Also, a homemade chair design can be more easily adapted to your child’s particular needs.

On the next pages we give information that may help you decide about different wheelchairs and effective low-cost ways to make them.

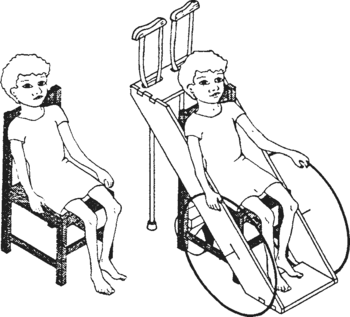

You can make a fairly effective low-cost wheelchair by attaching bicycle wheels or wooden wheels to an ordinary wooden chair. Also, it is easier to attach aids or supports to a wooden chair than to a metal chair. This design is adapted from Healthlink Worldwide’s booklet, Personal Transport for Disabled People (see "How-to-Do-It Reference Materials for Wheelchairs, Wheelboards, and Other Seating").

REMEMBER: A wheelchair needs to satisfy the rider—not just the maker. Before (and after) buying or making a chair, think carefully about the different features that will help it best meet the needs of the particular child and family.

When buying or making a wheelchair (or any other aids), consider:

- Cost. Keep cost low but quality high enough to meet the child’s needs (see above).

- How long will the chair last? The longer the better, unless it is only for temporary use.

- How easy and quick is it to make? The easier and quicker the better, as long as it meets your needs.

- Availability of materials. Make use of local low-cost, good-quality resources (local wood, cheap metal, used bearings, bike parts, etc.).

- What tools and skills are needed to make it? If welding equipment or skills are not locally available, a wooden chair may be a more practical choice.

- How easy will it be to adjust or repair? Wood chairs that are bolted together are often the easiest to adjust or add special supports to.

- Weight. The lighter the better, while making sure it is strong enough.

- Strength. Heavier persons need stronger chairs and stronger axles. (A small child’s chair may be supported by a bicycle axle attached on one side only. A bigger child needs the axle to be supported on both sides, or a stronger axle.)

- Width and length. The narrower and shorter the better while meeting the child’s needs (but not so short that it tips over easily).

- How easily can it be moved — by the child sitting in it or by someone behind? How easily can it be tilted back to go over rough spots? Lifted up stairs? Transported? (Does it need to fold to take up less space?

- How well is it adapted to the particular child’s wants and needs? Is it comfortable? Does it allow the child to sit in a healthy position?

- Fit and growth factor. How well does it fit the child now? How long will it continue to fit her? Can it be adjusted to fit her as she grows?

- How well is it adapted to living situations , the home, local customs, width of doorways, surface of floors and roads, curbs and other barriers?

- Appearance. Is the chair attractive? Does the child take pride in it? Do other children want to ride it?

In considering choices for the design, building materials, and features of a wheelchair, be sure to carefully consider the above questions.