Hesperian Health Guides

Clean Production

HealthWiki > A Community Guide to Environmental Health > Chapter 20: Preventing and Reducing Harm from Toxics > Clean Production

Contents

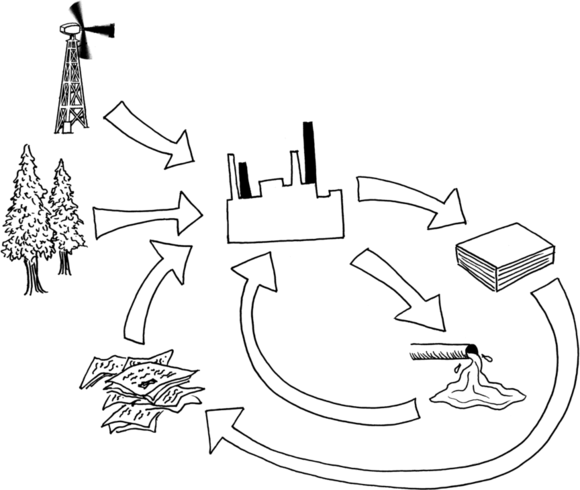

How a paper factory uses clean production

and forests

A paper factory uses trees, water, electricity, and chemicals such as chlorine. A clean production paper factory reduces pollution by using:

- mostly recycled paper, and trees from sustainably managed forests.

- a renewable source of energy (such as solar or wind energy) rather than electricity from fossil fuels such as oil or coal.

- no chlorine or other toxic chemicals.

- as little water as possible. Water is reused several times and then treated to make it safe to put back in the environment.

Most industries can use a clean production process. Heat from factories can be used to generate electricity, and waste products from one process can often be used as materials in another. Clean production can reduce waste to almost nothing. And because clean production reuses materials and energy, it also saves money.

But because companies usually do not pay to clean up or prevent the pollution and harm they cause, they usually must be forced by popular pressure or government regulation to change to clean production methods.

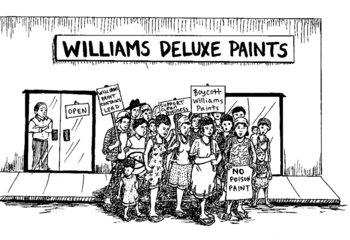

Promoting cleaner businesses

When business owners and workers understand how chemicals and industrial waste can harm them and everyone in the community, they are often willing to make changes in production materials and methods to reduce harm. Sometimes, however, it is necessary to pressure them in both positive and negative ways to achieve changes that will benefit community health. There are various ways to influence business to choose cleaner production methods.

Government can: ban or regulate the use of toxic chemicals and dangerous production processes; refuse to purchase products that are produced in harmful ways; provide funds to businesses to change to cleaner production methods; charge less taxes to businesses that use clean production, and collect more taxes from businesses that use harmful methods.

People can: educate themselves, business owners, and workers about the dangers of toxics and the benefits of cleaner production methods; boycott (refuse to buy) products made by a company or sold by a business that is polluting; let others know about nontoxic alternatives that can be substituted for toxic products; use the media to both denounce toxic corporate practices and celebrate the successes of nontoxic, sustainable businesses.

Workers can: learn about, follow, and enforce rules about safe handling of toxics, and write protections against toxics for workers and the community into their union contracts.

Cleaner small businesses

Sometimes, small business owners do not fully understand the harm toxics can cause. When they and their workers use, store, and dispose of toxic chemicals in unsafe ways, they are usually just trying to save money, time, and labor. After all, many businesspeople live in the same communities they are polluting, and are friends and neighbors of the people affected. Or they may know about cleaner production methods but feel they cannot afford the cost of making changes. But over time, the high costs of health care for injured workers and environmental clean-up for damage in the community will often end up costing more time and money, rather than saving it.

When small businesses change to cleaner production practices, they help make the entire community, and their future as a business, more sustainable.

Dyeing

Many dyes are made with heavy metals and other toxic chemicals. The waste from making dyes is often poured into waterways, filling them with pollutants that are dangerous and difficult to clean up.

How to reduce pollution

Small businesses in the dye industry can reduce harmful waste by following these guidelines:

- Avoid the most toxic dyes, such as azo dyes, and look for safer alternatives. Azo dyes, known to cause birth defects, are commonly used in printing, textiles, paper manufacturing, pharmaceuticals, and food industries.

- Control the amount of toxics used.

- Reuse byproducts from dyeing as materials to make other products.

- Reuse cleaning water to make the next batch of dye.

- Use high-pressure hoses for cleaning to reduce the amount of wastewater.

- Label and store toxic materials in secure areas away from waterways.

Tanneries

Leather tanneries use large amounts of water, salts, and toxic chemicals, such as different forms of chromium. At the end of the tanning process, these chemicals are often dumped as waste into rivers and other waterways. As a result, communities around tanneries often have highly contaminated drinking water.

In the short term, these toxics can cause bronchitis, asthma, and other breathing problems. In the long term, repeated exposures can cause birth defects and cancers.

How to reduce pollution

Some tanneries use nontoxic or less toxic production methods. Traditional methods of tanning use animal parts for safer and cleaner tanning. For tanneries that use chromium, there are ways to recover and recycle chromium so that less is used, and less ends up as waste. This reduces costs as well as toxic pollution. The water used in tanning baths can be recycled, and the wastewater can be treated to make it safer before dumping.

Cleaner production in tanneries

The city of León, México is famous for its high quality leather shoes. The tanneries in León are small businesses, important to the economic survival of the community. Unfortunately, the tanning operations used to dump chemical waste directly into local waterways, causing serious illness.

Over many years, León passed laws to regulate the pollution, but the tanneries almost never obeyed them. Many tannery owners thought reducing pollution was too costly and would hurt their businesses.

However, when thousands of birds died from pollution in a wetland near León, the local trade organization representing the tanneries began to look for ways to reduce pollution without hurting business. This was when they learned about clean production.

Over the next several years, the trade organization helped the tanneries reduce pollution, and many of the tanneries changed their practices. They did not do this only because they wanted to protect local drinking water or migrating birds. They also did it because they saw that clean production could save them money and produce higher quality leather.

Tanneries in Africa and Asia worked with the United Nations Industrial Development Organization (UNIDO) to find different ways to recover and reuse the chemicals used in tanning. UNIDO’s Cleaner Production Project showed that more than half of the pollution from tanneries could be reduced through careful and efficient use of natural resources — using smaller amounts and using them with greater care.

The tanneries of León learned from the UNIDO project and began to practice cleaner production methods. First, they used a new process in which more of the chromium in the tanning bath came in contact with the hide, and less ended up as waste. Next, an enzyme (a natural product that causes chemical changes) replaced the harmful chemicals used to soften hides. Some tanneries that produced lower quality leather began using vegetable tanning rather than chromium tanning, eliminating a very toxic and costly part of the process.

Tanneries that could find no alternative for chromium began reusing it, rather than dumping it after the first use. The same was done with the large amounts of chemical-filled water. Some tanneries built wastewater treatment systems to clean the water and recycle it for reuse, protecting and preserving water resources.

Now the leather workers of León know about clean production. When you ask them why they use these new methods, they may tell you it is to protect local waterways. But they will also tell you they now produce higher quality leather for a lower cost than before.

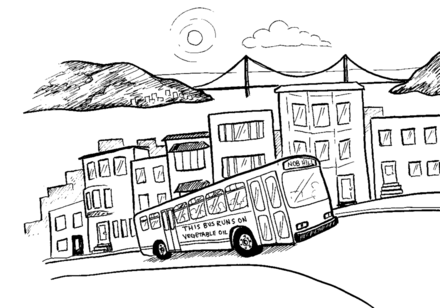

A taste of clean production

The beautiful views from the hills of San Francisco, USA, attract tourists from around the world. So does the variety of foods served by its many small restaurants. But with so many restaurants, waste oil from cooking became a problem, clogging sewers and costing the city money. The city requires that all restaurants use a “grease trap” to prevent oil from entering the sewers, but emptying and cleaning grease traps is expensive. Many small businesses owned by recent immigrants cannot afford it.

San Francisco’s Public Utilities Commission, in charge of the city’s sewers, decided that instead of charging large fines to restaurants for not disposing of their oil properly, they would offer a solution. They would collect the waste oil and use it to run city buses!

When the diesel engine was invented, it burned light fuels such as vegetable oil. But because petroleum was cheap and plentiful, and the companies that produced it were powerful, most diesel engines began to use petroleum. Now, with the serious pollution and global warming caused by petroleum, people are returning to vegetable oil as a cleaner and less costly fuel.

Vegetable oil can be used after making a few changes to a diesel engine, or the oil can be turned into “biodiesel,” which can be used with no changes. Burning biodiesel dramatically reduces the air pollution that causes asthma and cancer, and it does not cause global warming. Compared to other fuels, such as natural gas, it is also less expensive.

Making biofuels by recycling waste oil is different than growing a new crop just for fuel. It keeps a waste product out of the sewers and puts it to use.

To make clean production work, the San Francisco Public Utilities Commission hired native speakers of many languages to visit restaurants and collect waste oil. The restaurant owners no longer pay to get rid of their oil, and the city benefits by having fewer clogged sewers and cheaper fuel for its buses.

Now, instead of smelling like traffic, the streets of San Francisco smell like fried food. Which brings more tourists than ever to local restaurants.