Hesperian Health Guides

Local ventilation

Local ventilation is sometimes called an extractor, an exhaust vent, or local exhaust ventilation. Local ventilation does not replace general ventilation. To protect workers, both systems need to be working.

These jobs need local ventilation:

- grinding, sawing, and sanding, because they create large amounts of dust and debris. Workstations with a lot of dust should also be cleaned well with vacuums, wet towels, or sponges to prevent the dust from spreading.

- gluing, soldering, and spot cleaning, because the chemicals used for these release vapors.

- jobs that use mists or sprays, because these move quickly through the air and can be harmful to the lungs.

- jobs that use or produce chemicals or dust that can catch fire or explode.

Some work processes should be completely enclosed in a machine to prevent chemicals or dusts that are very dangerous to health from getting in the air. Maintenance workers must be especially careful about exposure to chemicals when they open and repair these machines (see Enclosed machines).

Kinds of local ventilation

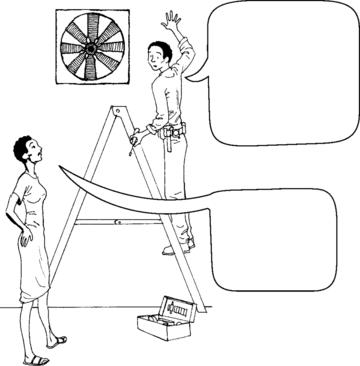

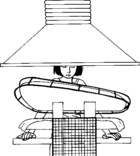

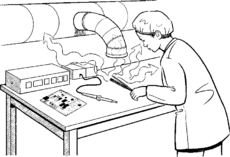

Extractor hoods are placed above or next to the work area. If hoods are close to the work, they will remove more of the hot and dirty air. If they are too far, some of the fumes might get in the air you breathe. Fans, or people walking by, opening doors or windows, can change the direction of the air. Do the activity Follow the air!

Local extractor vents are placed very close to the work or on the tool itself. Vents should be downwind from the work you are doing, so they pull the air away from your face instead of towards it.

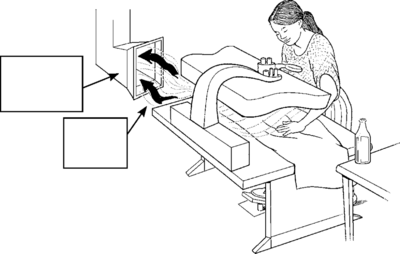

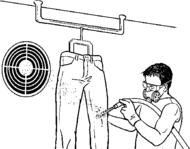

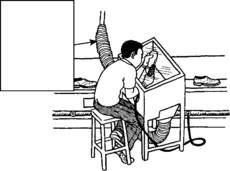

Local exhaust booths protect workers by putting a protective barrier between the worker and the work, and then use ventilation to remove most of the dust or fumes from inside the booth. Workers need the right kind of gloves to protect their hands (see Gloves).

All local ventilation systems need regular cleaning and maintenance. Regularly check and replace filters, fans, motors, belts, and gauges. When the filters or air ducts are blocked with dirt, more dust or chemicals stay in the air workers breathe. Filters should be cleaned or disposed of safely. If the local ventilation is not working or not working well enough to extract all the dust and chemicals being produced at your workstation, you will breathe them in. Demand that the boss fix the ventilation. In the meantime, use masks and gloves to protect yourself from these dangers.

If the local ventilation is not working or not working well enough to extract all the dust and chemicals being produced at your workstation, you will breathe them in. Demand that the boss fix the ventilation. In the meantime, use masks and gloves to protect yourself from these dangers. (See Chapter 18: Personal protective equipment.)

Check your local ventilation

A smoke test is an easy way to see the direction, flow, and power of the fresh air coming into a work area and the dirty air leaving. There are many kinds of smoke testers. Some produce a lot of smoke that can harm your health. Some are as small as a match and produce less smoke, which is safer. Smoke tests can be done with smoke bottles, smoke pens, powder puffers, and smoke matches. (Where ductwork contains smoke detectors, this test will not work.)

If you do not have any of these, use other things that produce a good amount of smoke. Do not use fire around flammable or explosive chemicals, dusts, or processes. Another way to check how the air moves around you is to attach tissue to a stick that will not bend and move it close to the extractor.

- Use several sticks of incense, cigarettes, cigars, or a bundle of leaves or paper that burns slowly and creates a lot of smoke, like a bundle of sage. If you are working with flammable or explosive chemicals or processes, do not use anything burning. Instead, fill a bottle that has a small nozzle with baby powder that will drift in the air like smoke.

- Turn on the extractor closest to your workstation.

- Stand or sit where you do your work.

- Make smoke. Where does it go? How does it move? Does anything change when people walk by and block the ventilation?

- If the smoke goes directly to the extractor and all of it goes inside, it is probably working well.

- If it moves towards your face, towards other workstations, or in other directions, something is probably wrong. Maybe not enough air is coming in, maybe movement around you affects the direction of the smoke, or perhaps the extractor vent is not powerful enough. Have your co-workers do this activity, too.

- If all the smoke does not go in the extractors, you and your co-workers can pressure your boss to find someone qualified to fix the problem.

Activity

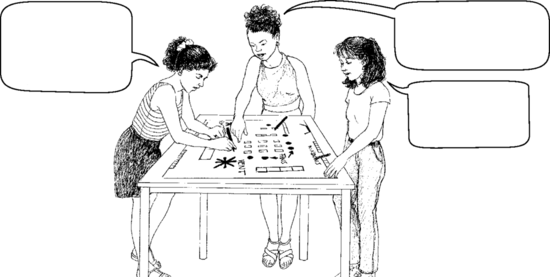

Follow the air!

|

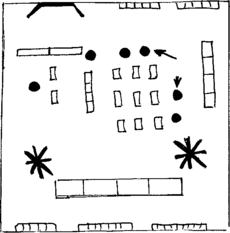

1. Draw a map of your factory’s ventilation If you work in a large factory or if you work inside cleanrooms, it might be useful to also make a map of your work area. |

There’s an exhaust vent on the ceiling, on top of this area.

The fan in front of that machine doesn’t really work.

These windows aren’t open during the day. |

- Where does air come in? Draw every source of air, even if it is "when a door opens and closes." Do some sources of air bring in more or less air? Is it fresh air from the outside or air from other parts of the factory?

- Where does the air go and how does it move inside the factory? Air is hard to track. But try to draw where the air goes after it comes in. Show fans and which way they move air. By making a steady stream of smoke or powder and following it, described in Check your local ventilation, you can see how air moves in the factory.

- Where are the vents or extractors that remove the air? In some factories, windows and doors might be the only way air goes out of the factory.

- Where are the work areas where people are getting sick? Areas where there are problems may not have good ventilation. (See Bad ventilation makes you sick.)

| 2. Inspect the ventilation system in your factory Ask maintenance workers for help. They can tell you about the ventilation system or take (or let you take) photos of it. Work with them to understand how poor ventilation harms their health too, and let them know you are not blaming them for any problems. |

Is there anything blocking the air coming in or going out of vents?

How dusty are the vents?

Can you see or smell dust or chemicals?

Is there anything outside the factory blocking air from coming in or going out?

Is the ventilation system on all the time, or just sometimes?

Are fans and extractors strong enough? |

| 3. Find out how the ventilation system is maintained Fans, extractors, and vents get dirty and can break. Cleaning, inspecting, and replacing blocked or broken fans, vents, and extractors should be included in a good ventilation plan. |

- Are they cleaned? Ask maintenance workers if they know who cleans them and how often. They may also have filters that need to be cleaned or replaced. Do they have any record of the last time they did this? Also ask about what they use to clean them.

- Who checks them and how often?

- How quickly are parts or units replaced if they are broken?