Hesperian Health Guides

Better ventilation improves everyone's health

HealthWiki > Workers' Guide to Health and Safety > Chapter 17: Ventilation > Better ventilation improves everyone's health

Some changes to ventilation systems are very easy to make and maintain. Some cost more. You may also come up with other ideas to improve ventilation that might not require the boss to be involved.

Form a workers’ ventilation committee

Invite your co-workers to build a team of workers that can focus on ventilation problems. Anybody can join the team, because every person in the factory will benefit from better ventilation.

work station ✓✓✓✓✓

Find out what ventilation issues there are in your factory through surveys, inspections, and mapping activities (see Chapter 3: Organizing to improve worker health). Share any information you gather with all workers.

Seek support from people who know about ventilation, such as maintenance workers, ventilation installers, health organization staff, occupational safety and health professionals, and others.

Reach out to your co-workers, supervisors, and the boss. Ventilation requires constant attention. Getting an extractor may be a great step forward, but it will not protect your health if it is not regularly checked and cleaned. Keep pushing for monitoring, testing, maintenance, cleaning, as well as worker involvement at every step.

Think of ways to improve ventilation while workers organize to win bigger changes. For example, moving workstations to improve air flow while demanding that the boss install extractors. When discussing what changes to make, make sure to include all workers.

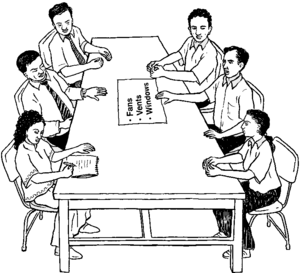

Talk with people in unions, worker centers, and NGOs to learn about how others have campaigned for better ventilation (what worked or did not work), to get help reviewing information you have collected, and for advice on how to improve your workplace.

Reach out to government officials and learn about laws about ventilation in your country, and research the ways in which you can push to enforce them. If your current laws are weak or leave ventilation regulation to the companies, seek support from legal clinics and organizations about how to influence or change laws. See if you can find support in international conventions (see Appendix A: Laws and the struggle for decent, healthy, and fair work or the "Codes of Conduct" for the brands being made in your factory.

Talk with community groups working against air pollution in your community. The polluted air extracted from the factory can affect the health of everybody inside and outside the factory. Join campaigns to reduce and prevent air pollution and increase pressure on government officials to monitor and regulate ventilation in the factory.

A cooler factory

The Ocean Sky factory in El Salvador got very hot in the middle of the day. Managers always locked the doors and windows to "reduce theft" so no fresh air could come in. Workers would sweat right onto the clothing they were making for Puma and Adidas.

But ventilation was not the only problem at Ocean Sky. When workers got together to talk about the things that needed to change, they realized there were so many! With the help of several unions, the women’s group Mujeres Transformando, and international organizations, they decided to fight for all of them at once.

To create a good ventilation proposal, workers collected research and involved experts and the government. When the government official came to test the temperature at the factory, he was shocked at how high it was. The official told the boss he needed to open windows and doors, install extractor fans, and place cooling fans around the factory. By now the united effort with unions and NGOs had gotten the attention of the brands that gave the factory contracts. They pressured the boss to make these changes.

A few months later, another organization came to check on the changes. All the windows were open, but the air flow was still bad. Shelving units blocked air flow through the factory. The boss moved them to a better place.

Now workers do not sweat as much as before, but many still have allergies and breathing problems. They are discussing how to get the boss to install local extractors for the machines that produce dust.