Hesperian Health Guides

General ventilation

A good general ventilation system removes some of the dust, heat, and chemicals from the air and replaces it with safe, clean air to breathe. Good ventilation also keeps the temperature and humidity of the workplace at a healthy and comfortable level.

Good ventilation requires regular inspection and cleaning of all vents and filters to keep the system working well and prevent polluting the air outside the factory. This protects people in the community from being made ill from factory pollution.

Heating, Ventilation, and Air Conditioning (called HVAC) is a complex kind of general ventilation system used in electronics factories to better control air flow, temperature, and humidity.

Contents

How general ventilation works

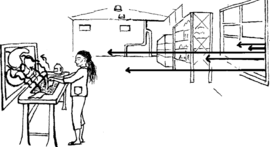

General ventilation should move fresh air into the workplace and move the dirty air coming from the work out.

Fresh air is important because it dilutes the amount of chemicals in the air you breathe so it causes less harm. Do the activity Follow the air! to see how fresh air moves through your factory.

Windows and fans

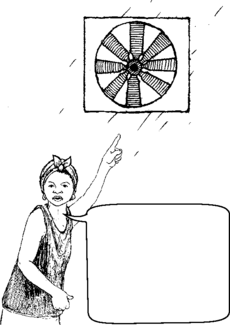

Factory windows and doors bring in fresh air but this might not be enough to keep the air flowing and stop people from getting sick from chemicals in the air. Wall fans can move fresh air into the factory or dirty air out, but need to be checked and cleaned regularly to make sure they are working well.

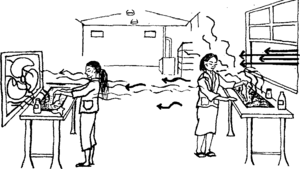

Fans move air through the factory

Directional and ceiling fans help guide air through the factory and can help keep an individual worker cool. If the fans in your factory are not guiding clean air in and dirty air out, they are likely just moving dust and chemicals around in the factory.

If your factory is hot and fans blow hot air at you, drink lots of water and pay attention to health problems caused by heat.

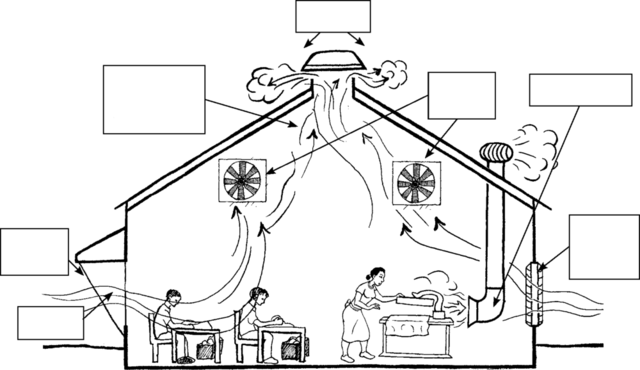

Vents and exhaust fans move dirty air out

A roof vent lets the warm air out. This creates a draft that pulls fresh air in to replace it.

An exhaust fan will only pull air from the area close by and will not help general ventilation. The exhaust vents will not work well or may not work at all if there is not enough fresh air coming in from outside. An exhaust fan that is too weak will not pull out enough dirty air.

Air from local ventilation extractors should be filtered before it is released into the community or back into the factory, so it carries fewer chemicals that may make people sick. When local exhaust ventilation is not filtered, chemicals in the air being removed can cause health problems, especially for pregnant women and young children near the factory. (See Chapter 33: Pollution from factories.)

Is air flow helping or harming you?

Special general ventilation

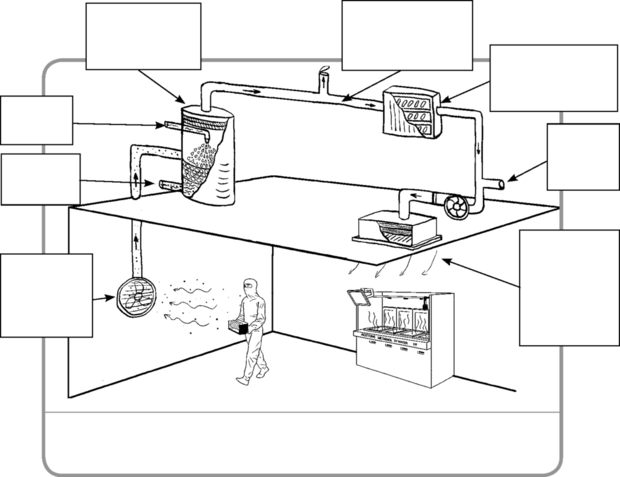

Heating, ventilation and air conditioning (HVAC) systems are used in work areas like "cleanrooms" that must be kept at the right humidity and temperature.

To work well, HVAC systems should:

- balance air in and air out. If the fans bringing air in are too strong, they overwhelm the vents extracting the air, and not enough dirty air will be removed. Dusts and chemicals will accumulate in the cleanroom.

- clean and filter the air. Dirty air, full of dusts and chemicals, is extracted, scrubbed, and filtered. Almost 70% of this air is sent back into the cleanroom after it is cleaned. If scrubbers and filters are not monitored and replaced, they might not remove all chemicals.

- control the temperature and dampness. Air conditioning keeps the work area cool and dry to lower the amount of fumes and vapors, and the flammability of the chemicals used in the cleanrooms. The temperature might be too cold. (See Chapter 15: Heat and cold.)