Hesperian Health Guides

Reduce and remove toxic chemicals

HealthWiki > Workers' Guide to Health and Safety > Chapter 8: Chemical dangers > Reduce and remove toxic chemicals

- Steam and detergent may work as well as chemical cleaners or solvents.

- Cleaner, more efficient processes and techniques can reduce the need to use chemicals for cleaning and degreasing.

- Low solvent/high pigment paints and low solvent coatings can coat the same number of parts with less solvent. These coatings also dry faster.

- A brush, roller, syringe, sponge, ladle, or other tool can help a worker to apply the smallest amount of chemical to the smallest area. When the worker uses less chemical, there is less waste and less mess to clean up.

- Cleaning up excess chemical right away protects other workers from exposure. For example, wiping excess oil from machined parts keeps oil from spreading to other surfaces that will later have to be cleaned.

- Spot cleaning uses less cleaner or solvent than cleaning the whole piece.

Contents

Find a safer chemical

Your factory should use the mildest, safest chemical products needed to get the job done. For example:

- Use non-chlorinated hydrocarbon solvents instead of chlorinated solvents like methylene chloride or TCE (trichloroethylene).

- Use water-based cleaners, glues, paints, dyes, and coatings instead of products that contain a solvent.

- Use weaker-strength acid and alkaline baths and washes. They often work just as well as stronger ones. Use small plastic or metal pellets instead of sand as a blasting material to eliminate silica dust.

- Use vehicles with electric motors indoors instead of those that produce toxic fumes because they burn diesel, gasoline, or compressed gas.

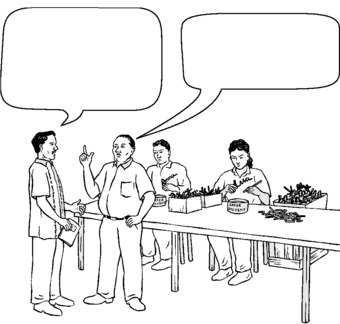

We now use a safer chemical

Our factory in Mexico makes plastic drinking straws shaped to spell people’s names. They are kind of a silly product, but there was nothing silly about what they did to our health.

We all had the same health problems. We suspected these problems were caused by the chemical we used to fuse the straws together. The containers we used did not have labels, so we asked the storeroom workers for a label from one of the large containers.

I talked to my neighbor Miriam, who always knows what to do. She brought us and the label to the office of the Comité Fronterizo de Obreras (CFO), an organization that works with workers in our area. The CFO had a whole box of chemical information sheets. We found the sheet for methylene chloride. It was very hard to understand. The CFO organizer explained what all the scientific terms meant and we learned methylene chloride does more than just give us sore throats and headaches. It can harm the liver and cause cancer!

When the boss refused to do anything about it, we took the information about methylene chloride to the local office of the national environmental protection agency, PROFEPA. We asked them to inspect the factory.

We had to pressure them several times. The inspectors finally came, but they told the boss ahead of time. Just before the inspection, the boss replaced the methylene chloride with another chemical.

The boss claimed he didn’t want to pollute the air outside, but he did not care if we breathed dangerous chemicals all day inside the factory!

PROFEPA never required the boss to install the local exhaust fans. But after the inspection, the boss kept buying the less dangerous solvent, even though it was more expensive.

Ban the most dangerous chemicals

Some chemicals are too dangerous to use in factories or anywhere else. Thanks to years of protest by workers, OSH professionals, doctors, and health advocates, many countries prohibit the use of:

- lead and other toxic metals in pigments, dye, paint, and other coatings

- rosin or colophony flux for soldering

- solvents such as glycol ethers, methylene chloride, benzene, and carbon tetrachloride

- diesel and gasoline burned in engines used indoors, such as in forklifts

- sand for sand blasting

Manufacturers have developed safer products and processes that do not depend on these most dangerous chemicals. And workers, environmentalists, and responsible businesses are lobbying to ban:

- lead, chromium hexavalent, and cadmium in electronics, including solder

- chlorinated and fluorinated (halogenated) hydrocarbon solvents

- plastic made from vinyl chloride (PVC)

- brominated flame retardants

Banning very harmful chemicals not only protects production workers, it also protects recycling workers and consumers, and keeps pollution out of our air and water.