Hesperian Health Guides

Different Braces for Different Needs

HealthWiki > Disabled Village Children > Chapter 58: Braces (Calipers) > Different Braces for Different Needs

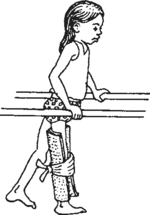

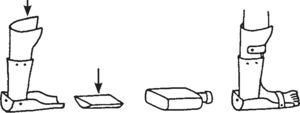

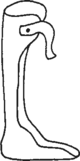

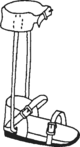

The main lower-limb brace types are:

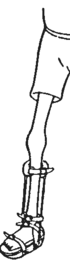

| Foot brace | Below-knee braces (ankle brace) |

||

| usually made of molded plastic | for weakness or deformities in the lower leg, ankle, and foot |  | |

| for deformities in the foot (not ankle) such as severe flat foot |  |

||

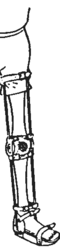

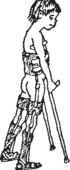

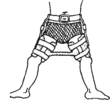

| Above-knee brace (long-leg brace) | Above-knee brace with a hip-band | ||

| for weakness in the upper leg and knee — possibly also ankle and foot |  |

for severe weakness in hips and legs |  |

Contents

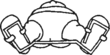

Less commonly used types include:

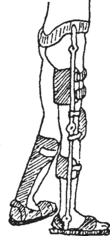

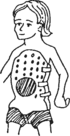

| Leg-separating braces | Foot-positioning night brace | Body brace or corset | Body brace with leg braces | ||

| for dislocated hips or damaged head of thigh bone | for holding the feet, legs, and hips at a set angle when they tend to turn in | for curve of the spine |  |

for body and back weakness together with hip and leg weakness |  |

|

|

||||

Different materials and ways to make braces

As we discussed in Chapter 56, an ideal brace should:

- serve its purpose well (help the child walk or function better)

- be comfortable

- be lightweight and strong

- be as attractive as possible

- be easy to put on and take off

- do no harm

- be low cost

- be easy and quick to make with local tools and limited skills

- use local or easily available materials

- be easy to repair and adjust as the child grows or develops

- be long lasting

Unfortunately, no brace will meet all these requirements. As much as possible, put the child’s needs first.

In this chapter we give ideas for making different braces using various materials. When deciding how to make a brace, carefully evaluate both the child’s needs and the available resources (see Chapter 56).

| Sometimes it is wise to start with a simple low-cost temporary brace or splint to see how well it works and what the challenges are. |

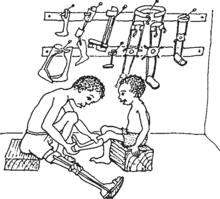

|

Keep old and outgrown braces for testing on new children before final braces are made. But take care not to discourage the child by making him use braces that do not fit him well. |  |

Examples of very simple, low-cost braces and splints:

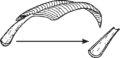

| A temporary leg splint of cardboard, folded paper, or the thick curved stem of a dried banana leaf, or palm leaf. | Aluminum tube finger splint |

|

|

| Mango seed finger splint | Bamboo ankle splint |

| |

| Remove the woody coat of a mango seed, and wrap the coat firmly onto the finger. It will dry into a firm splint. To change its shape, first soak it in water. | A piece of seasoned bamboo can be heated and bent. |

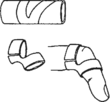

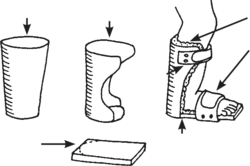

Plastic cup ankle braces for night or temporary use on a small child.

|

For a small baby:  padding

straps of leather, canvas, or Velcro, if possible

rivets

rivet or nail wood to cup.

piece of wood

plastic cup

cut like this

|

For a child:  3 cups cut and riveted together

Make a flat inner sole out of cloth or wood.

Or cut the foot piece from a flat plastic bottle.

Add straps to fasten the brace around leg.

|

Metal or plastic braces

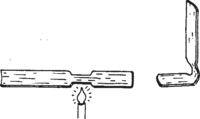

Modern, high-quality braces are usually made out of metal or molded plastic.

The best metal is a mix or “alloy” of aluminum and steel which is both light and strong. However, this is very costly and often hard to get. Pure aluminum is very light, but breaks easily, especially when you try to bend it. Steel is cheaper and easier to bend and weld, but is much heavier.

The best plastic for braces is probably polypropylene, which is strong, light, and fairly easy to shape when hot.

Pre-formed metal parts for making these braces are sold at orthopedic supply stores. Unfortunately, they are usually much too expensive for a community program. However, sometimes you can get large orthopedic centers to donate old braces, from which locking knee joints and other pieces can be used to build high-quality metal or plastic braces. Also, many broken or outgrown braces are lying in the corners of thousands of homes. A campaign to get families to donate these can greatly reduce the costs of making high-quality braces.

Low-cost metal or plastic braces can be made in a village shop. They can be made simply, with or without joints. Since children grow quickly, they often need a larger brace every 3 to 6 months. Therefore, keeping cost low and work simple is essential. (See "Precautions in Providing a Child with Aids, Equipment, and Procedures")

Metal and plastic braces each have advantages and disadvantages. We discuss these on "Fitting Plastic or Metal Braces", "Metal Braces", and "Plastic Braces".

In Mexico, we have found that for most children who need below-knee braces, plastic works best. And the children (and parents) like it more.

| However, a child with a lot of muscle tightness (due to spasticity or contractures) which pulls his foot a lot to one side, like this, may need a metal brace with an ankle strap. After the brace is on, the strap is tightened to pull the foot into a better position. |

Above-knee braces can be made using a combination of plastic and metal. |  |

Whenever possible, equip your village shop to make both plastic and metal braces. That way, you can make what seems most appropriate for each child.