Hesperian Health Guides

Chapter 16: Falling workers, falling objects, and vehicle injuries

HealthWiki > Workers' Guide to Health and Safety > Chapter 16: Falling workers, falling objects, and vehicle injuries

Contents

Prevent falls from high places

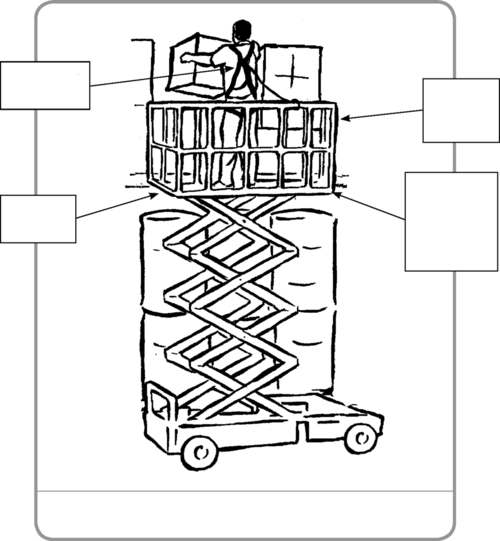

Working above the floor on a stable platform is the best way to prevent a worker from falling, and to prevent tools or parts from falling into the work area below. A platform can be moveable or fixed in one place. The platform should be large enough for a worker to do his job with room for tools and materials.

Prevent injuries from falling objects

Workers can be severely injured or killed by tools or materials falling or dropped from above. To prevent things from falling onto workers, make sure:

- work areas and walkways are not directly below overhead rail systems, platforms, or stored materials.

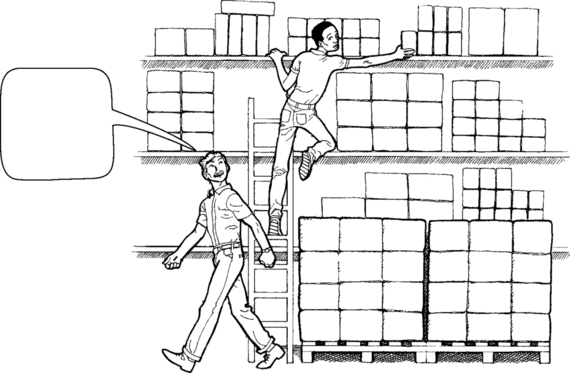

- materials and containers are not stacked too high or unevenly. This will keep them from tipping over. Mark stacking height limits on shelves.

- shelves and raised storage platforms are strong enough to hold the materials stored on them and are anchored to the floor. Post and follow weight limits.

- no workers are below high shelves during loading and unloading.

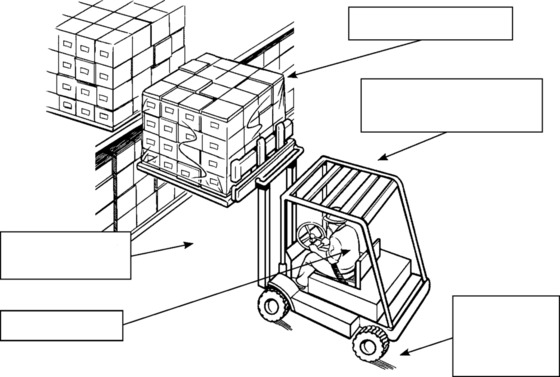

- lift truck operators are trained to safely operate, load, and unload the lifts.

- vehicles are equipped to protect the driver from falling loads.

- workers wear hard hats under elevated work areas. A hard hat can reduce the seriousness of some injuries caused by falling materials hitting your head, but will not protect you from larger objects. Neither will it protect your neck and body from being injured.

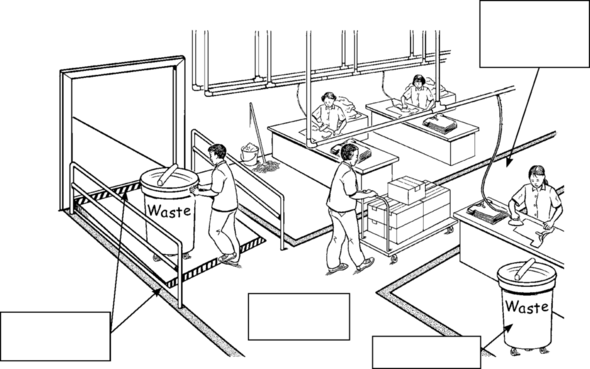

Prevent slips, trips, and falls

Uneven floors, holes in the floor, changes in floor levels, wet floors, and wires and debris on the floor cause workers to slip, trip, and fall.

Many falls can be prevented by:

- repairing rough floors.

- keeping walkways clear.

- marking changes in floor level, such as stairs and ramps, with paint or different surfacing, so you can see them.

- cleaning up water, oil, and chemical spills immediately.

- cleaning up debris, dirt, and dust regularly.

- fastening loose cords to the wall or floor with tape.

- adding better and more light.

- wearing slip-resistant shoes.

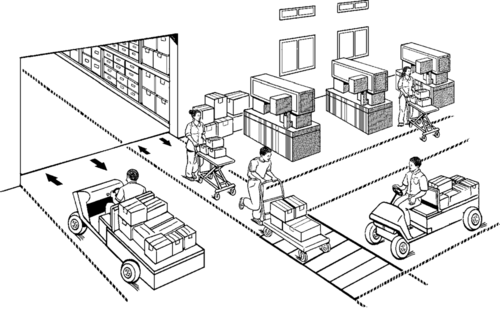

Prevent vehicle injuries

Some of the dangers from motor vehicles are the same in and outside factories. Injuries from motor vehicles on roads and in factory zones can be prevented by separating vehicle traffic from walkways and clearly marking each. Make sure workers are trained to operate vehicles safely, and that vehicles are regularly inspected and maintained.

When motors burn fuel indoors, workers breathe dangerous exhaust from the burned gasoline or diesel fuel. Propane-powered vehicles are safer, but electric vehicles burn no fuel so they are the safest.

To protect people from vehicles:

- Mark walkways and separate them from vehicle traffic lanes.

- Put a stop sign where vehicle traffic crosses a walkway, and post speed limits.

- Make walkways wide enough for the number of people using them.

- Leave vehicles space to move around work areas without colliding with machines, equipment, materials, other vehicles, or workers.

- Clear walkways of parked vehicles, stored supplies, and debris.

- Park vehicles where they do not block lanes or walkways.

- Store materials and place large machines so drivers and people walking can see ahead clearly.

- Train drivers to operate vehicles safely, including how to load and unload them.

- Maintain and repair vehicles regularly.

After a worker is killed, factory improves parking lot

Silvia used to work at Solectron in Mexico. Every day, she would catch a van to her factory. One morning as she was walking towards the gate after being dropped off, a van carrying other workers hit her and ran over her leg.

Her friends and the van driver tried to help. One ran to get the nurse from inside the factory. But the nurse just stood there, looking confused. She wanted to put Silvia in a wheelchair even though she could not move. Finally somebody brought a stretcher. They put Silvia in the van and drove very fast to the hospital.

After surgery, Silvia got a very bad infection. But nobody wanted to take responsibility for her injuries or medical care, neither the transport company who owned the vans nor Solectron. So the hospital refused to treat her. Without medicines, her infection got worse.

Her family contacted a lawyer from CEREAL, a labor organization in Mexico. They tried to get the transport company to make their insurance pay, but it was too late. Silvia died in a few days from a completely treatable infection.

After her death, CEREAL had a meeting with Solectron, the van company, and Silvia’s family. Both companies agreed to pay the maximum compensation allowed by law for the death of a worker. This is how companies take responsibility, always too late.

But the question remained: Why did this happen? Many workers had complained about the vans and parking lot at Solectron. There was no system. Vans from different companies came and went, with no signals or safe crosswalks. Workers had to dodge the vans that competed to leave the lot first.

Solectron fought with the transport company over responsibility for Silvia’s death, but they also began to change the parking lot at the factory. They installed lighting, which helped both drivers and people walking to see better and feel safer. They installed signals to direct traffic and placed speed bumps to slow the vans. Now there is also a safe walkway from the drop-off zone to the factory.

These changes came at a great cost for Silvia and other workers who had been injured trying to get to work. But change finally came.