Hesperian Health Guides

Sewing

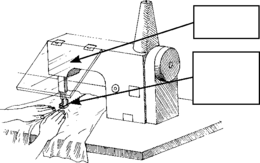

Machine injury: Needles in the machine can cut your fingers and hands and can break and fly into your eyes. Moving parts can catch hair and pull it out or pull a person into the machine.

- Machine guards and shields can protect workers from getting cut, stabbed, or injured by needles.

- Enclose drive shafts and moving belts (above and under the table!) to keep hair, clothing, or anything else away from moving parts.

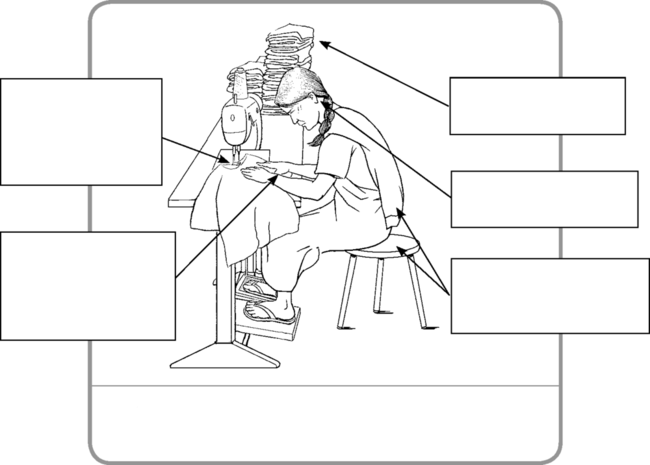

Strain and injury: Sewing machine operators do the same movements over and over. Reduce overuse injuries caused by repeating the same movements:

- Take breaks, rotate among jobs, and stretch and strengthen different muscles.

- Improve your workstation to support your body and reduce the reaching, strain, and strength needed to operate your machine. (See Chapter 7: Ergonomics.)

Noise: Sewing machines and riveting machines are very loud. When many are running at the same time, the noise level can be very high. Too much noise can permanently damage your hearing.

- Ask an OSH professional to measure the noise level.

- If noise levels are too high, wear ear protection.

Light: Good lighting helps you see your work without straining your eyes. Not enough light makes you squint or get too close to the work, which weakens the eye muscles and can lead to blurry vision (see Chapter 14: Light).

- Have the boss install better lighting.

- Do exercises to strengthen and stretch the muscles around your eyes.

Fires: Many things can start a fire — bad electrical connections, chemical spills, dust, or smoking cigarettes. But fires in garment factories quickly turn deadly when factory owners do not provide fire extinguishers or sprinklers and do not maintain safe and clear exits. See Chapter 11 for information about how to organize to prevent fires, to stop them if they start, and to demand policies in the factory that protect all workers from fires.

Trapped behind locked doors and windows

The Ali Enterprises factory fire in Karachi, Pakistan in September 2012 was one of the deadliest fires in history, killing 289 people.

A boiler exploded and the chemicals stored near it caught fire. The factory owner had locked all the exit doors "to stop theft" and there were no emergency systems to stop the fire. Workers on the top floors of the 5-story building tried to jump out of windows. Others found no escape and were suffocated by smoke or burned to death.

The factory had passed a safety audit just a few weeks before the fire. Safety inspectors either missed or ignored unsafe conditions, or were misled by the owners. But even without corruption, an occasional audit cannot compare to an active, joint worker-management safety committee, present in the factory all day, every day.

In response to this tragic fire, 70 Pakistani trade unions and community groups formed the Workers’ Rights Movement. They are demanding compensation for injured workers and families, the arrest of the factory owners, and enforcement of safety laws in factories.