Hesperian Health Guides

Protect workers from chemicals

HealthWiki > Workers' Guide to Health and Safety > Chapter 8: Chemical dangers > Protect workers from chemicals

Contents

- 1 Keep chemicals off your skin and eyes

- 2 Reduce the amount of chemicals in the air

- 2.1 Reduce fumes and vapors from open containers

- 2.2 Reduce fumes from chemical baths

- 2.3 Reduce fumes from soldering and plastic molding

- 2.4 Clean work areas regularly

- 2.5 Reduce mists and dusts

- 2.6 Ventilation reduces chemicals in the air you breathe

- 2.7 Enclose machines

- 2.8 Use respirators if you must

- 3 Prevent chemicals from getting in your mouth and belly

- 4 When you smoke, chemicals get in your mouth

- 5 Prevent spills and leaks

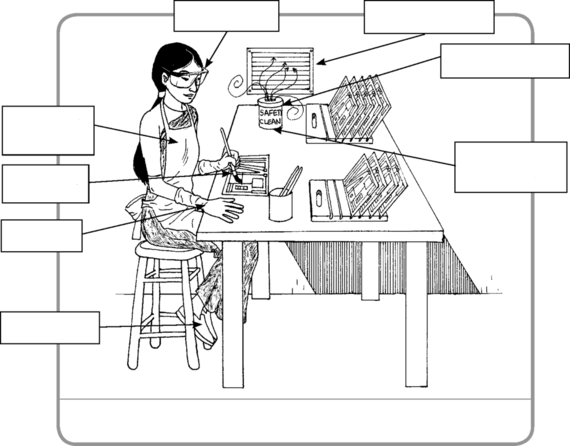

Keep chemicals off your skin and eyes

When machines and equipment are not properly set up or in good working order, they leak and cause spills and accidents. The boss is responsible for providing the right equipment and hiring and training enough workers to protect you from chemical leaks, splashes, and accidents. But even if conditions in your factory are not ideal, workers can often arrange their work areas and job tasks to prevent chemicals from splashing, dripping, or leaking.

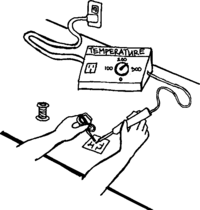

Use tools to handle chemicals

Avoid touching chemicals with your hands. Use brushes, ladles, and long-handled tools to mix, measure, or apply chemicals. The boss should supply these tools, but workers can sometimes adapt an existing tool or make a new one for a specific job. Also, use tools that fit your body. If a tool is too large or too heavy, it is bound to lead to more spills and waste.

Use protective clothes and equipment

Cloth, leather, and rubber gloves and aprons, long sleeves, and covered legs and feet can keep dust, paste, powder, and other solid chemicals off your skin. These can also protect you from very small splashes of liquid chemicals. (See Chapter 18: Personal protective equipment.) If protective equipment is used, the boss should provide you without charge the correct protective clothing for the dangers you face, and he should replace it at no cost when it is worn or damaged.

Protective equipment does not eliminate the dangers you face — it only limits the harm these dangers can cause you. Protective clothes can be hot and uncomfortable, and gloves, aprons, masks, or goggles can be dangerous if they do not fit properly. If they are too large or too loose, they may not protect you at all. Gloves that are too big make it difficult to handle tools and do precise work. Long, loose clothing can get caught in machinery or cause you to trip and fall.

If chemicals get into your clothes, remove the clothes and wash your skin right away.

Reduce the amount of chemicals in the air

When there are chemicals in the air, we can easily breathe them into our lungs. Mists and dusts can get onto skin, be absorbed through eyes, and get into mouths. Even if we can’t completely get rid of chemicals in the air, there are ways to limit how much gets into our bodies.

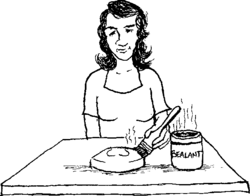

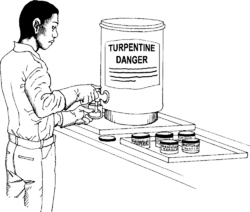

Reduce fumes and vapors from open containers

Keep vapors out of the air by covering containers when they are not being used. Make openings smaller to fit the tools you are using. Try using a smaller tool that applies just the amount of chemical you need. The less chemical you use, the less vapor goes into the air you breathe.

|

|

| Breathing too much chemical vapor is dangerous. | Cover containers and use a small amount of the chemical. |

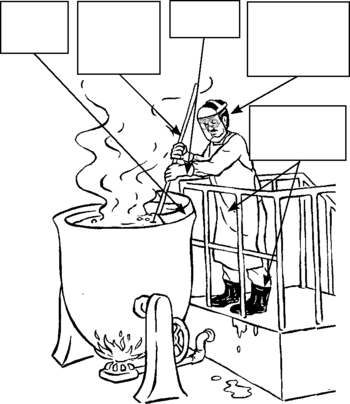

Reduce fumes from chemical baths

|

| Covering a chemical bath you are not using keeps vapors out of the air. |

Chemical baths release mists and vapors which can get inside your nose, eyes, mouth, and skin. When baths do not have rim ventilation, some factories add anti-foam agents to the baths to reduce misting. Others cover the surface of the baths with plastic chips or balls to lessen the amount of mist that escapes. Fewer vapors escape when heated baths are kept from getting too warm and are cooled when not in use.

Reduce fumes from soldering and plastic molding

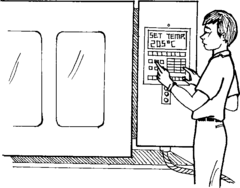

|

A maximum soldering heat of 200° to 250°C prevents lead fumes. |

Solder and flux make fumes and smoke when soldering irons or wave soldering machines are too hot. If there is lead in the solder, the fumes are very dangerous. Local exhaust ventilation can remove fumes at the source. Workers can control the temperature on newer soldering irons and soldering machines to prevent overheating the solder. Fumes are less dangerous when soldering and welding are done at lower temperatures.

| To keep plastic from creating dangerous fumes, workers need time to adjust and maintain their machines. |  |

Plastic processing machines melt plastic and push or blow it into a mold. To reduce fumes, plastic should be heated only enough to melt and mold it. Machines should be set up for each new batch of plastic and maintained carefully to control the heat and processing times.

Clean work areas regularly

Chemicals in the form of dust, soot, and mist get on work tables, walls, and floors all over the factory. If they are not cleaned up right away, the chemicals can get on the skin or clothes of any worker who touches them. Regular cleaning reduces the amount of chemicals in the whole factory. Cleaning is especially important where toxic substances are used.

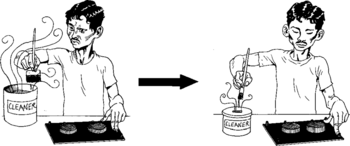

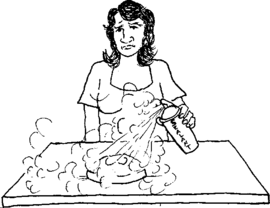

Reduce mists and dusts

When you spray a chemical, a lot of it is wasted in the air or on other surfaces below or behind the part you spray. If you must use spray to paint or coat parts, use the least amount to cover the part. A spray booth will help keep the chemical out of other work areas.

Spraying flammable chemicals can create explosive vapors which can explode or catch fire. Only spray flammable chemicals in a spray booth or workstation with strong exhaust ventilation.

Do not use flammable chemicals around processes that can spark or are very hot, such as soldering, hot baths, ovens, or plastic molding machines.

|

|

| Spraying puts a lot of chemical into the air. | Use a brush or sponge to put the chemical only where it is needed. |

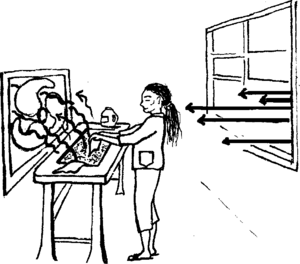

Ventilation reduces chemicals in the air you breathe

You may not be able to prevent chemicals from getting into the air in the factory. But ventilation can help reduce the amount of chemicals you breathe. Local exhaust vents or extractors remove chemical vapors before they spread inside the factory. Roof vents and exhaust fans help move air with dust and chemicals out of the factory building. While this ventilation helps protect workers in the factory, if it is not filtered and cleaned it just dilutes and moves the chemical danger to the surrounding community. (For more information, see Chapter 17: Ventilation.)

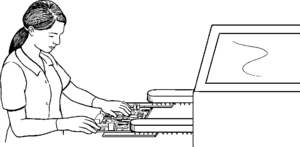

Enclose machines

Large machines that produce a lot of chemical vapor, mist, or fumes, are safest when they are enclosed in a large, ventilated box. The box stays closed when the machine is working, and is opened to load, adjust, clean, and repair the machine. Exhaust ventilation removes vapors and fumes from the machine and the factory. Some boxes collect the vapors instead of venting them, and filter the air before releasing it.

Many machines in electronics, shoe, and garment factories are enclosed, such as automated soldering machines, plastic processing and molding machines, and ovens. These machines collect fumes, mists, and solids. They should be cleaned by workers trained in how to clean and dispose of the waste. Maintenance workers need to use the highest level of protective equipment available for these chemicals in order to protect themselves from exposure.

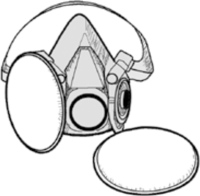

Use respirators if you must

|

| Respirators have to be tested on you to see if they fit you well. See Check that your respirator fits and works. |

Respirators may sometimes be necessary, but they are not the best way to protect against inhaling chemicals. The best ways are to use only chemicals that are not dangerous to breathe, to enclose machines so they do not give off fumes, and to have good ventilation. If you must use a respirator, the ones that protect most completely are respirators with filters or separate air supply. They are hot, uncomfortable, and make breathing difficult. Their filters and other parts need to be cleaned and replaced often.

Respirators are the last resort. Only use them if you think you might be exposed to chemicals in the air. Maintenance workers and workers who handle the more dangerous chemicals need respirators with the correct filters or with air supply. See the various types of respirators and their uses.

|

| Wash off chemicals with plain soap and water. |

Prevent chemicals from getting in your mouth and belly

No worker tries to get toxic chemicals in her mouth. But it is easy for chemicals to get on your hands or clothes, and from there into your mouth. Even if you wear gloves, you can get chemicals on your hands when you take the gloves off or if they leak. When chemicals get on your hands, they can also get on anything you touch.

To keep chemicals out of your mouth, wash your hands before you touch food, dishes, or cigarettes. This is especially important for workers exposed to lead, asbestos, pigments, solder, and toxic dust from grinding, foundries, and metal casting.

Our water is poison

Tap water is supposed to be safe to drink in the United States. But in Silicon Valley, California, drinking water was polluted by the sloppy practices of the electronics industry. When electronics companies began making semiconductors here in the 1980s, we didn’t know much about them. Neither did the government. So the companies did whatever they wanted. They dumped toxic waste into the water, and storage containers leaked thousands of liters of chemicals into our soil.

First they claimed it wasn’t happening. Then they said it was not a problem — the chemicals didn’t spread and weren’t toxic. But we discovered the chemicals poisoned the water. We fought hard for the companies to take responsibility. Government and independent agencies tested the water and found many problems. Silicon Valley had more toxic areas than anywhere in the USA. After 30 years, it has some of the most toxic water in the country, solvents in the water are leaching upward, and cleaning up will take decades.Keep chemicals out of drinking water

Good health depends on drinking enough water. But when chemicals get in the water or on the cups you use, drinking water can become a source of illness.

- Make sure the factory provides you with enough clean water to drink.

- Keep water containers covered so chemicals and dust cannot get in.

- Put water bottles in a safe place. Wash your hands before opening them.

Never put a chemical in a container that is used for food or drinks, or that looks like a food or drink container. People expect a soft drink bottle to contain soft drink, not a dangerous chemical. Someone may drink from the bottle by mistake.

Never put food or drink in a container used for chemicals. Even if the container has been washed, it may still have small amounts of chemicals inside that can get into the food or drink – and you!

When you smoke, chemicals get in your mouth

Smoking cigarettes in the workplace adds dangerous chemicals to the air all workers breathe, whether they smoke or not.

Chemicals from work get on cigarettes

If you have chemicals on your hands and you pick up a cigarette, the chemicals get on the cigarette. When you put the cigarette with chemicals on it in your mouth, you ingest some of the chemicals. When you smoke a cigarette with chemicals on it, the chemicals burn and you breathe them in.

Cigarette smoke is dangerous

Cigarette and cigar smoke contain dangerous chemicals from the burning tobacco, paper, and the chemicals with which they are treated. The smoke carries small particles that irritate the eyes and throat. When breathed in, the chemicals go deep into the lungs and cause lung cancer, emphysema, asthma, and other serious diseases, and worsen health problems from other causes. Millions of workers die from smoking every year and the big tobacco companies make millions of dollars causing their deaths.

A man is a monkey with one in his face.

Take warning, dear friend.

Take warning, dear brother:

There’s a fire on one end and a fool on the other.

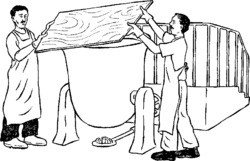

Prevent spills and leaks

It is easier and safer to prevent chemical spills than to clean them up.

- Design chemical storage and mixing rooms to be fireproof, well ventilated, temperature controlled, and easy to clean.

|

| Transferring solvent to smaller, labeled containers. |

- Transport chemicals in closed containers that cannot break or shatter. If you move containers of liquids or powders on carts, use carts with sides and spill trays to catch leaks.

- Use small containers of chemicals in work areas. Preventing and stopping leaks is easier when bulk chemicals and large containers are kept in a separate storage area.

- Store chemical containers so openings or valves are at the top.

- Transfer chemicals from one container to another by using drip-preventing spouts for liquids, and scoops or other tools for solids, such as pastes, powders, and pellets. Use a tray under the containers to catch leaks and spills.

- Put static control mats throughout the area where flammable solvents are stored to prevent static electricity from causing them to explode. When transferring solvents, you can also prevent explosions by connecting a ground wire to each container. Or only ground one container and attach a wire from it to other containers as a common ground.

- Control heat during plastic processing. When melted plastic gets too hot, it can leak or overflow.

- Inspect and maintain containers, pipes, pumps, valves, and machines that could leak chemicals, especially their manual and automatic shutoffs. When damage and worn parts are noticed early, they can be repaired or replaced before causing a leak.

Clean up a small chemical spill

The most important thing after a chemical spill is to protect yourself and your co-workers. If you cannot safely clean up the spill, help everyone leave the area.

- If someone is more prepared than you to clean up a spill — if there is a person trained to do this work — call that person first.

- Always wear protective clothing, including rubber boots, safety glasses, and gloves, to clean up a chemical spill.

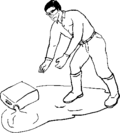

| 1. Control the spill Find the cause of the spill and stop it. Shut down leaking equipment. Turn a tipped-over container upright. Put a leaking container inside another. |

|

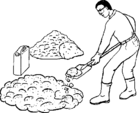

| 2. Contain the spill Absorb the chemical by putting soil, sand, sawdust, clay, or similar material on the spill. If the material may blow away, cover it with a plastic sheet. |

|

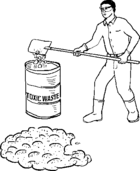

| 3. Clean up the spill Scoop the material into metal drums or thick plastic containers. Label clearly with the chemical’s name and "Waste!" Do not wash the chemical away with water. This will spread the chemical and make the problem worse. The boss is responsible for disposing of chemical waste properly. If he does not, report him (anonymously) to local environmental authorities. |

|

What should be available in your factory:

- training to clean up spills

- evacuation practice

- a place where tools, protective equipment, clean-up materials and containers can be kept close to where chemicals are stored or used

- telephone numbers of the agency to report a spill or accident, and emergency services to call for help