Hesperian Health Guides

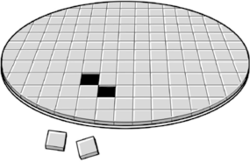

Making the chip on the wafer

HealthWiki > Workers' Guide to Health and Safety > Chapter 4: Electronics factories > Making the chip on the wafer

To make individual chips on the silicon wafer, workers put the wafers through several machines that cover them with chemicals and expose them to ultra-violet (UV) light. The chemicals and the light build the design for each individual chip on the wafer. The process of layering chemicals and exposing them to light is called "photomasking." The process of removing unwanted chemicals to complete the design is called "etching."

Even though photomasking and etching happen inside closed machines, workers can be exposed to chemicals when:

- machines, pipes, and vents have leaks or are not working well. Leaks can be found by regularly inspecting all equipment, and checking and replacing air quality monitors. Then leaks can be fixed as soon as they are noticed. A planned maintenance schedule keeps workers, production, and communities safer than just responding when there is a failure. Factories that run 24 hours a day in shifts might not respond to leaks as well or as quickly as factories that have time to repair a machine without affecting production.

- workers open machines, pipes, and vents to clean and repair them. Maintenance workers or engineers who open the machines and come into direct contact with chemicals face the most danger, but all workers are affected when chemicals get in the air.

Contents

To protect all workers, maintenance workers should:

- follow all shut down, lock out, and tag out procedures when they repair machines.

- wear the highest level of protective equipment (see Chapter 18: Personal protective equipment).

- make sure other workers leave the area if chemicals may be released.

Photomasking dangers: photoresist chemicals

Workers, activists, and health professionals believe photoresists are one of the most toxic chemical mixes used in making electronics. The companies that make photoresists usually refuse to disclose which chemicals and how much of each are in them, saying that is a "trade secret." However, the danger they pose to health is no secret.

Photoresists contain a mix of chemicals from 4 basic categories: sensitizers (chemicals that react to heat or light), solvents, polymers, and additives. When exposed to light, some of the chemicals in photoresist break down into other chemicals, called byproducts. These chemical byproducts can also be very harmful to workers’ health.

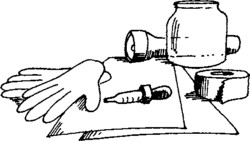

Photoresist is quickly absorbed by the skin. Wear the right kind of chemical-resistant gloves, clothing, and respirators to protect against photoresist and its byproducts (see Chapter 18: Personal protective equipment).

Photomasking dangers: UV lights

The UV lights inside photomasking machines are supposed to turn off when the machine is open and workers are loading or unloading wafers. UV light can quickly damage your eyes, even in an enclosed machine. Workers in this area need UV-protected polycarbonate goggles, nitrile gloves, and face masks (see Chapter 18). Clothing must cover the entire body, especially the wrists. Even a small gap between shirt cuff and glove can let UV light burn any exposed skin.

UV light bulbs break easily. As they contain mercury, a broken UV light not only poses a risk injury from cuts, it also exposes workers to mercury.

When a UV light breaks, small pieces of mercury scatter. This is also true with compact flourescent lights (CFLs), but these contain much less mercury. Turn off any machines, heaters, fans, and air conditioners. Leave the area and make sure all workers are out before closing the door. Inform the supervisor so maintenance can clean up the spill.

Clean up a mercury spill

If you have to clean up a mercury spill, you will need gloves, an eyedropper, 2 pieces of stiff paper or cardboard, 2 plastic bags, sticky tape, a flashlight, and a glass container with a lid and with water in it.

- Do not touch the mercury.

- Remove watches and jewelry. Mercury sticks to other metals.

- Shine a flashlight on the area to make the mercury easier to see, even during the day.

- Wear chemical-resistant gloves if possible. If you have only latex gloves, wear 2 pairs.

- Use small pieces of stiff paper or cardboard to gather the mercury and broken glass into a small pile.

- Use an eyedropper to suction up the mercury beads, and put the mercury in the glass container with water.

- Pick up any mercury that is left using sticky tape.

- Place tape, eyedropper, gloves, and cardboard in a plastic bag.

- Label the bag "mercury waste" and put the bag in the glass container with the water in it.

- Seal and label the container. Put it inside another plastic bag.

- Dispose of it as toxic waste.

Etching dangers: wet etching

Wafers are dipped into several baths containing nitric, acetic, and hydrofluoric (HF) acids to remove photoresist. This work area must be enclosed and have strong local exhaust ventilation.

Acids can quickly burn your skin, eyes, and insides, so you need acid-resistant protective equipment, including respirators if your ventilation is not good enough or if you move materials between workstations. There must be a shower and eye wash station nearby (see First aid when a chemical touches your skin or eyes).

Etching dangers: dry etching

Wafers are sprayed with fluorinated hydrocarbons and heated with radiofrequency (RF) radiation. The heat from the radiation causes the gases to move, "attack," and remove the photoresist chemicals. RF radiation can harm your nervous system and cause reproductive problems. The best way to protect yourself from radiation is to limit how much time you work with it and use barriers and PPE to shield yourself from it (see Radiation).

Fluorinated hydrocarbons are dangerous because they accumulate in our bodies. Over time, even small amounts can build up and make us sick. People who breathe or touch them might have problems breathing and skin irritation. Some cause heart problems, reproductive problems, and cancer.

Protect workers from etching chemicals:

- Regularly check that machines seal completely. Fix leaks immediately.

- Ventilation must be strong enough to remove all chemical fumes. There should be emergency ventilation in case of a spill.

- All workers should have PPE. Maintenance workers need special PPE. An OSH professional can help identify the PPE you need.

- Etched wafers should sit in a ventilated "waiting area" before they are removed, to reduce the amount of fumes in the air for everyone.

- Pregnant women should not work with fluorinated hydrocarbons. These chemicals can harm babies inside the womb.

Adding more layers and special qualities to the wafer

Wafers pass through several processes to:

- add more layers onto the chips already designed on the wafer (oxidation).

- make some of the layers more conductive to electricity (ion implantation).

Dangers from dopant gases

Dopant gases such as arsine, phosphine, diborane, and boron are heated by RF radiation so they will form layers with different electrical properties on the surface of the wafer. Workers are exposed to dopant gases when loading and unloading wafers from the machines, when changing gas cylinders, and when repairing or cleaning machines.

Dopant gases might make you feel weak, tired, sleepy, or confused, and might give you a headache or muscle cramps. They can also make you have problems breathing, faint, or feel paralyzed. If you have any of these signs:

- Leave the area immediately.

- Remove your protective equipment and clothes, and wash your entire body with water and soap.

Don’t wait until you feel sick to put on protective equipment or stop production to get a machine fixed.

See First aid when you breathe in a chemical. See information on dopant gases.

|

We noticed a strange smell and complained. Tests showed high levels of arsine. It turned out the wafers were releasing the gas when they came out of the machine. They gave us fancy respirators after that. But what would have happened if arsine didn’t smell? |

|

Arsine smells like garlic. If you can smell it, you are exposed to levels that can cause harm. See arsine. |

Dangers from heat and fire

Dopant gases burn easily. Some explode when heated or when they accumulate, so vents and machines must be cleaned often, on a planned maintenance schedule. Some machine parts, such as pumps, must be cleaned frequently because the oil in the pumps absorbs gases and can harm workers. Also, the machines can get very hot. Workers in this area can get burned from accidentally touching the machines. See First Aid for burns.

Dangers from X-rays

The combination of RF radiation and dopant gases generates X-rays, a form of radiation that can cause cancer and severe damage to the reproductive system for both women and men. X-rays are also used during inspection of the wafers, to see if they have enough metal. See more information on the health effects of X-rays and other radiation.

Dangers from adding metals to the wafer

To make electrical connections between the different parts of the chip, metal is added to the wafer. Aluminum is most commonly used, but so are chromium, copper, tin, lead, nickel, gold, silver, titanium, and platinum. Some metals cause more harm than others, but all are easier to breathe or accidently ingest as gases or vapors. Find information about metals.

Protect workers from:

- Dopants: Make sure all dopants are extracted before opening machines. Maintenance workers who clean or repair the machines should have airsupplying respirators and personal protective equipment for chemical exposure and heat (see Chapter 18: Personal protective equipment).

- X-rays: Machines should have X-ray shields. All workers in areas where X-rays are present need badges that detect X-ray levels. Shielding and badges must be checked regularly. If badges show high levels of X-ray exposure, workers need to be transferred out of the area and given access to medical services.