Hesperian Health Guides

Chapter 14: Light

Many export factory workers must keep their eyes focused on small parts and details. To see well, your work area should be lit evenly and brightly. Too little, too much, or uneven light can harm your eyes and cause other health problems.

A factory without enough light in corridors and storage areas makes it harder for workers to see dangers and prevent accidents, harder to escape a fire, and can make people feel unsafe, especially women.

Make work safer

- Evaluate and install lighting in the work areas, storage room, bathrooms, stairs and hallways, around the entrance of the factory, and at emergency exits.

- Clean lights regularly and change broken or burned-out bulbs.

- Add general lighting if needed.

- Add task lights for work that is very detailed, such as sewing or cutting.

- Monitor glare and reflection and pay attention to any changes in the light that might be causing you problems.

How to know if light is a problem

The best way to find out if the lighting in your factory is harmful is to ask other workers:

- Do you need to bend over to see your work better because you do not have enough light?

- Do you have to work in uncomfortable positions to see well or to get away from a bright light?

- Do you often get headaches while working?

- Are your eyes tired, aching, dry, or irritated at the end of your shift?

Also pay attention to the lights in the factory:

- Are there lights or does light only come from outside?

- How far apart are the lights? Are they close together or too far apart?

- Are the lights bright enough?

- Does the light cause bothersome reflections or glare on windows, or shiny floors, tables, or equipment?

- Are the lights in good repair?

How to see better and protect your eyes

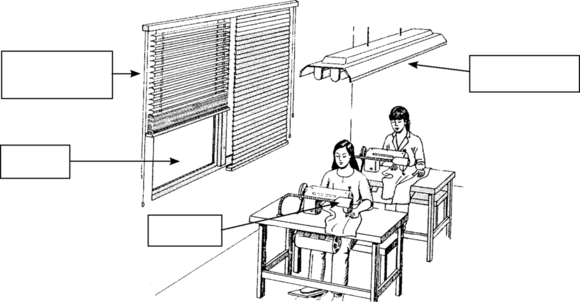

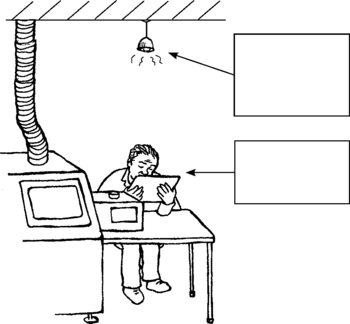

Add or change lights. Your factory may need more or different kinds of lights for different tasks. Lights that hang high above the work area should provide a soft, even light. Many workers need a task light they can adjust so there are no shadows on their machine or their work. Older workers may need brighter lights.

Use energy-saving light bulbs. Energy-saving bulbs give as much light as other bulbs. They may cost a little more, but use less energy, so they save money in the long term. Compact fluorescent bulbs contain mercury, so if one breaks, clean it up carefully and dispose of it as toxic waste.

Repair lights. Get the boss to repair flickering and broken lights, and broken window shades.

Clean lights regularly. Lights are often ignored, because they are too high up to clean. But cleaning them regularly can help improve visibility in the workplace. Clean dust from your task light every day.

Move for better light. If you cannot change or move the light, you may be able to turn or move your workstation, or change the way you sit or stand as you work. Some workers wear a hat with a brim to keep bright overhead light out of their eyes.

Cover surfaces that reflect light. To reduce glare, cover shiny surfaces with fabric, paint, or other coating that does not reflect light. Cover windows with cloth, curtains, or blinds when the sun is too bright or casts shadows.

Wear eye glasses. If your eyes are tired or irritated, or if you have trouble seeing your work, get an eye examination to find out if eye glasses can help. Each person’s eyes are different, and lenses for eye glasses are made to fit one person’s eyes. Eyesight changes over time. If you wear glasses and still have trouble seeing, you may need different lenses. Doing eye exercises can help keep your eye muscles healthy.